AL(T) Stainless Steel Multi-Stage Centrifugal Pump

The AL/ALT series is a cutting-edge, highly efficient, non-self-priming vertical multi-stage centrifugal pump, newly developed with reference to European standards. Featuring a groundbreaking industrial design, the product boasts an energy efficiency index (MEI) of 0.7 or higher. Utilizing an excellent hydraulic model and advanced manufacturing processes, the pump body’s flow passage components are crafted from high-quality 304 stainless steel through stamping and welding, while the shaft seal employs a hard alloy and fluororubber mechanical seal. Capable of handling a wide range of media, from tap water to industrial liquids, the AL/ALT series is suitable for various temperature, flow, and pressure ranges. With its compact structure, low noise levels, and small footprint, this pump offers significant energy-saving benefits.

Features:

- State-of-the-art design: The AL/ALT series incorporates a revolutionary industrial design, setting new standards in the field of vertical multi-stage centrifugal pumps.

- Superior energy efficiency: With an impressive Minimum Efficiency Index (MEI) of 0.7 or above, the AL/ALT series offers substantial energy savings compared to conventional pumps.

- Advanced manufacturing techniques: The pump body’s flow passage components are made from premium 304 stainless steel, precision-crafted through stamping and welding processes.

- Robust shaft seal: The shaft seal features a hard alloy and fluororubber mechanical seal, ensuring reliable performance and extended service life.

- Versatile media compatibility: The AL/ALT series is designed to handle a broad spectrum of media, ranging from tap water to various industrial liquids, making it adaptable to diverse applications.

- Compact and low-noise operation: The pump’s compact structure, coupled with its low noise levels and small footprint, makes it an ideal choice for installations where space is limited, and quiet operation is essential.

Applications:

-

1. Water Supply and Distribution:

– Water filtration and treatment in water plants

– Pressurization of main water distribution networks

– Water supply for high-rise buildings and skyscrapers

– Fire suppression systems and fire hydrant water supply -

2. Water Treatment Applications:

– Ultrafiltration (UF) systems for water purification

– Reverse osmosis (RO) systems for desalination and water treatment

– Distillation systems for pure water production

– Separators for oil-water separation and water treatment

– Swimming pool water circulation and filtration systems -

3. Industrial Pressure Washing and Cleaning:

– High-pressure washing systems for industrial equipment and vehicles

– Cleaning systems for industrial facilities and production lines

– Process water systems for manufacturing and industrial processes -

4. Industrial Liquid Transfer and Circulation:

– Cooling and air conditioning systems in industrial facilities

– Boiler feed water supply and condensate return systems

– Machine tool coolant and lubricant circulation systems -

5. Agricultural Irrigation:

– Large-scale farmland irrigation systems

– Spray irrigation systems for crops and orchards

– Drip and trickle irrigation systems for precise water application

These applications showcase the versatility of the AL/ALT series pumps in various sectors, including municipal water supply, water treatment, industrial processes, and agricultural irrigation. The pumps’ ability to handle different liquids, pressure ranges, and flow rates makes them suitable for a wide array of applications across multiple industries.

Service Conditions:

-

1. Liquid Characteristics:

– Thin and clean liquids without solid particles or fibers

– Suitable for slightly corrosive media -

2. Medium Temperature Range:

– Standard model: 0°C to +68°C (32°F to +154°F)

– Hot water model: 0°C to +120°C (32°F to +248°F) -

3. Ambient Temperature Range:

– -15°C to +40°C (5°F to +104°F)

-

4. Maximum Ambient Pressure:

– 1.0 MPa (145 psi)

-

5. Special Requirements:

– For liquids with higher density or viscosity than water, consult company representatives for proper pump selection and sizing

Note: Ensure that the pump materials and specifications are compatible with the intended application and operating conditions. Always refer to the manufacturer’s guidelines and consult with professional engineers for critical applications.

Motor Selection:

The AL/ALT series pumps are equipped with fully-enclosed, air-cooled, IE3 efficiency class motors. These motors feature high-quality NSK or SKF bearings for reliable operation and long service life. The motor specifications are as follows:

– Protection Class: IP55, providing robust protection against dust and water ingress

– Insulation Class: F, ensuring excellent insulation properties and thermal stability

– Working Mode: S1, suitable for continuous operation at constant load

– Voltage Levels: Available in 220V/50Hz and 380V/50Hz configurations to accommodate different electrical supply requirements

These motor specifications ensure that the AL/ALT series pumps deliver optimal performance, energy efficiency, and durability across a wide range of applications. The IE3 efficiency rating contributes to significant energy savings and reduced operating costs, while the high-quality bearings and robust construction minimize maintenance requirements and extend the pumps’ lifespan.

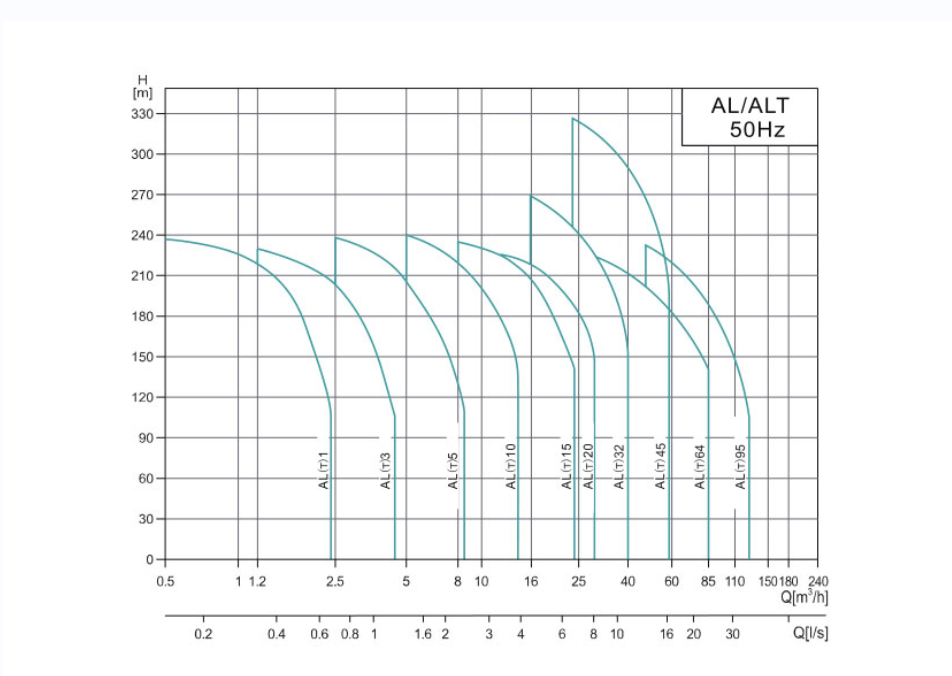

AL(T) Performance Curve:

| Model | Rated Flow (m³/h) | Flow Range (m³/h) | Max. Pressure (bar) | Motor Power (kW) | Max. Efficiency (%) | Temperature Range (°C) | Flange Pressure | Flange | Pipe Thread |

| AL(T)1 | 1 | 0.5-2.4 | 24 | 0.37~2.2 | 48 | Temperature Range (°C): Normal temperature type: 0°C ~68°C, Hot water type: 0°C ~120°C | PN25 | DN25 | R₂1¼ |

| AL(T)3 | 3 | 1.2~4,4 | 23 | 0.37~3 | 58 | PN25 | DN25 | R₂1¼ | |

| AL(T)5 | 5 | 2.5~8.5 | 24 | 0.37~5.5 | 70 | PN25 | DN32 | R₂1¼ | |

| AL(T)10 | 10 | 5~14 | 24 | 0.75~11 | 72 | PN25 | DN40 | Rc₂ | |

| AL(T)15 | 15 | 8~24 | 24 | 1.1~15 | 73 | PN25 | DN50 | Rc₂ | |

| AL(T)20 | 20 | 10~29 | 23 | 11~18.5 | 73 | PN25 | DN50 | Rc₂ | |

| AL(T)32 | 32 | 16-40 | 25 | 1.5~30 | 78 | PN25(40) | DN65 | / | |

| AL(T)45 | 45 | 22-58 | 25 | 3~45 | 79 | PN25(40) | DN80 | / | |

| AL(T)64 | 64 | 30-85 | 25 | 4~45 | 80 | PN16(25/40) | DN100 | / | |

| AL(T)95 | 95 | 48-124 | 25 | 5.5~55 | 81 | PN16(25/40) | DN100 | / |

FAQ:

Here are some frequently asked questions (FAQs) about the AL/ALT series pumps based on the provided information:

1. Q: What makes the AL/ALT series pumps energy-efficient?

A: The AL/ALT series features a cutting-edge industrial design that enables the pumps to achieve an impressive energy efficiency index (MEI) of 0.7 or higher, resulting in significant energy savings compared to conventional pumps.

2. Q: What type of liquids can the AL/ALT series handle?

A: The AL/ALT series pumps are capable of handling a wide range of media, from tap water to various industrial liquids, making them suitable for diverse applications across multiple industries.

3. Q: What temperature ranges can the AL/ALT series pumps operate in?

A: The AL/ALT series pumps are designed to operate in various temperature ranges, depending on the specific model. The standard model can handle liquids from 0°C to +68°C (32°F to +154°F), while the hot water model can handle liquids from 0°C to +120°C (32°F to +248°F).

4. Q: How are the pump body’s flow passage components manufactured?

A: The pump body’s flow passage components are crafted from high-quality 304 stainless steel through advanced stamping and welding processes, ensuring durability and resistance to corrosion.

5. Q: What type of shaft seal is used in the AL/ALT series pumps?

A: The AL/ALT series pumps employ a hard alloy and fluororubber mechanical seal for the shaft, providing reliable sealing performance and extended service life.