6 Inch Deep Well Pumps 6SE(K2) 264 GPM

The 6SE(K2) 264 GPM Deep Well Pump is a robust and efficient solution for your water extraction needs. Designed to operate at depths of 6 inches, this pump boasts a powerful flow rate of 264 gallons per minute, ensuring a consistent and reliable water supply. Ideal for agricultural, industrial, or residential applications, the 6SE(K2) model is built with durability in mind, featuring corrosion-resistant materials that guarantee a long service life even in harsh conditions. Its advanced hydraulic design offers high efficiency, reducing energy consumption and operational costs. Easy to install and maintain, this pump is a practical choice for those requiring high-volume water extraction. Whether you’re irrigating fields, supplying water to a factory, or managing a large property, the 6SE(K2) 264 GPM Deep Well Pump is an excellent investment that promises performance and reliability.

Features:

- Edible Oil-Filled Motor: The motor is filled with edible oil, ensuring stable and reliable operation. This unique feature also aids in the regulation of pressure, enhancing the pump’s efficiency and longevity.

- Pressure Regulating Membrane: This pump is equipped with a pressure regulating membrane, which maintains consistent pressure levels, contributing to steady performance even in varying conditions.

- Pump Casing with Plug Design: The pump casing incorporates a plug design, simplifying installation and maintenance. This feature ensures a secure and leak-proof operation, vital for deep well applications.

- Integrated Stage Floating Impellers: The pump boasts integrated stage floating impellers, designed to provide a seamless and efficient water flow. This advanced design reduces wear and tear, thus extending the lifespan of the impellers.

- High Flow Rate: With a capacity of 264 gallons per minute, this pump offers a high flow rate, ideal for applications requiring substantial water extraction, such as agriculture, industrial processes, and large-scale irrigation.

- Corrosion-Resistant Construction: Constructed with materials resistant to corrosion, the pump is suitable for use in a variety of environments, including those with harsh water conditions. This durability ensures long-term operation without significant degradation.

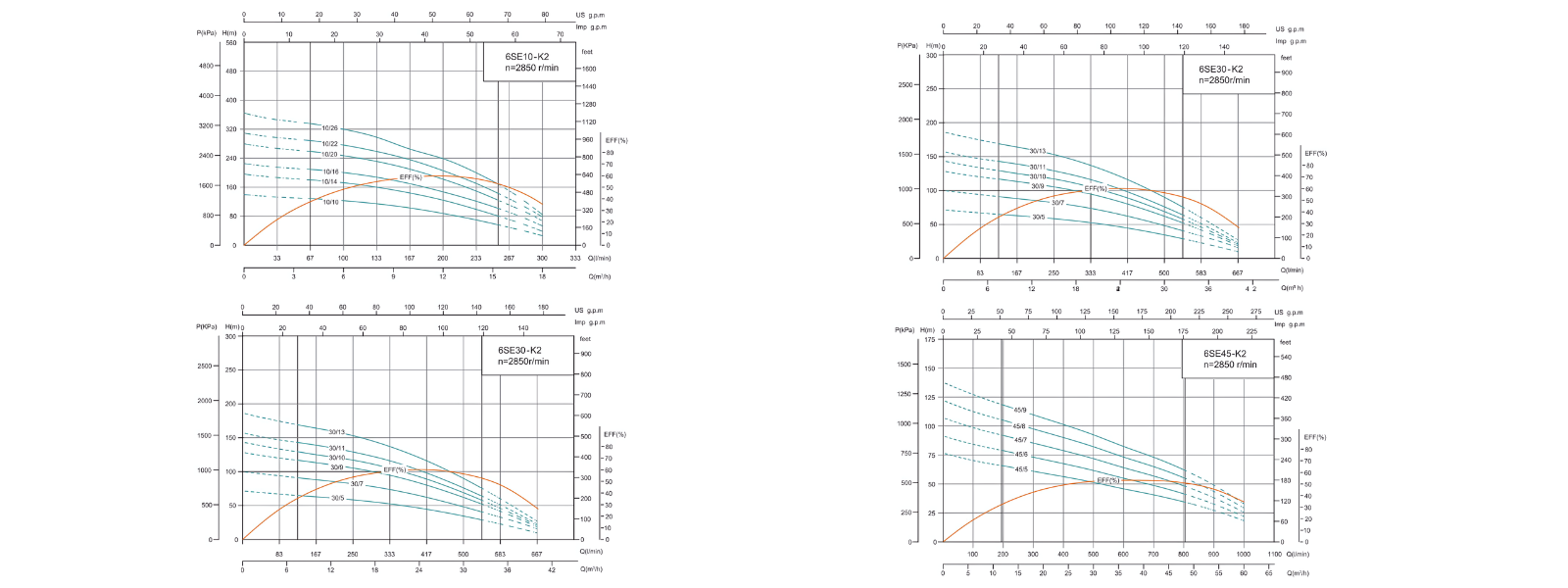

Performance Curve:

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | |

| 380V | 380V | l/min | 0 | 33 | 67 | 100 | 133 | 167 | 200 | 233 | 267 | 300 | |||

| 65E10/10 | 5.5 | 7.5 | 13 | H(m) | 140 | 133 | 129 | 129 | 115 | 100 | 100 | 69 | 48 | 25 | 125-53 |

| 65E10/14 | 7.5 | 10 | 18 | 198 | 186 | 181 | 181 | 160 | 140 | 140 | 97 | 67 | 34 | 181-77 | |

| 65E10/16 | 9.2 | 12.5 | 23 | 224 | 213 | 206 | 206 | 183 | 160 | 160 | 110 | 77 | 39 | 210-97 | |

| 65E10/20 | 11 | 15 | 26 | 280 | 266 | 258 | 258 | 229 | 200 | 200 | 138 | 96 | 49 | 260-119 | |

| 65E10/22 | 13 | 17.5 | 33 | 308 | 293 | 284 | 284 | 252 | 220 | 220 | 169 | 127 | 54 | 290-127 | |

| 65E10/26 | 15 | 20 | 35 | 364 | 346 | 335 | 335 | 298 | 260 | 260 | 200 | 150 | 64 | 330-167 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | |

| 380V | 380V | l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | |||

| 6SE18/6 | 5.5 | 75 | 13 | H(m) | 85 | 82 | 79 | 75 | 68 | 60 | 54 | 41 | 29 | 16 | 80-32 |

| 6SE18/9 | 75 | 10 | 18 | 128 | 124 | 119 | 112 | 102 | 90 | 82 | 62 | 43 | 24 | 120-47 | |

| 6SE18/11 | 9.2 | 12.5 | 23 | 156 | 151 | 145 | 137 | 125 | 110 | 100 | 76 | 53 | 29 | 146-58 | |

| 6SE18/13 | 11 | 15 | 26 | 186 | 179 | 179 | 169 | 149 | 137 | 118 | 90 | 66 | 34 | 176-71 | |

| 65E18/15 | 13 | 17.5 | 33 | 213 | 205 | 198 | 18B | 170 | 150 | 135 | 103 | 73 | 37 | 199-79 | |

| 6SE18/18 | 15 | 20 | 35 | 257 | 247 | 240 | 233 | 206 | 189 | 163 | 125 | 91 | 39 | 243-99 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | |

| 380V | 380V | l/min | 0 | 83 | 167 | 250 | 333 | 417 | 500 | 583 | 667 | |||

| 65E30/5 | 5.5 | 75 | 13 | H(m) | 72 | 68 | 64 | 59 | 53 | 45 | 35 | 23 | 10 | 65-29 |

| 65E30/7 | 75 | 10 | 18 | 100 | 94 | 88 | 82 | 73 | 63 | 48 | 32 | 14 | 91-41 | |

| 6SE3019 | 9.2 | 12.5 | 23 | 129 | 121 | 113 | 105 | 95 | 80 | 62 | 42 | 19 | 117~52 | |

| 65E30/10 | 11 | 15 | 26 | 143 | 134 | 125 | 117 | 105 | B9 | 69 | 46 | 21 | 143-64 | |

| 65E30/11 | 13 | 17.5 | 33 | 157 | 147 | 139 | 129 | 116 | 98 | 76 | 51 | 23 | 169-75 | |

| 65E30/13 | 15 | 20 | 35 | 186 | 174 | 164 | 153 | 137 | 116 | 90 | 60 | 27 | 195-87 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | |

| 380V | 380V | l/min | 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |||

| 65645/5 | 7.5 | 10 | 13 | H(m) | 76 | 71 | 66 | 61 | 56 | 51 | 46 | 41 | 35 | 27 | 18 | 66-36 |

| 65E45/6 | 9.2 | 12.5 | 18 | 92 | 85 | 79 | 73 | 68 | 62 | 55 | 49 | 42 | 33 | 22 | 80-43 | |

| 65E45/7 | 11 | 15 | 23 | 107 | 99 | 92 | 82 | 79 | 72 | 64 | 57 | 48 | 38 | 26 | 93-50 | |

| 65E45/8 | 13 | 17.5 | 26 | 122 | 113 | 105 | 98 | 90 | B2 | 73 | 65 | 55 | 44 | 29 | 106-57 | |

| 65E45/9 | 15 | 20 | 33 | 137 | 127 | 118 | 110 | 101 | 92 | 82 | 73 | 62 | 49 | 33 | 119-65 | |

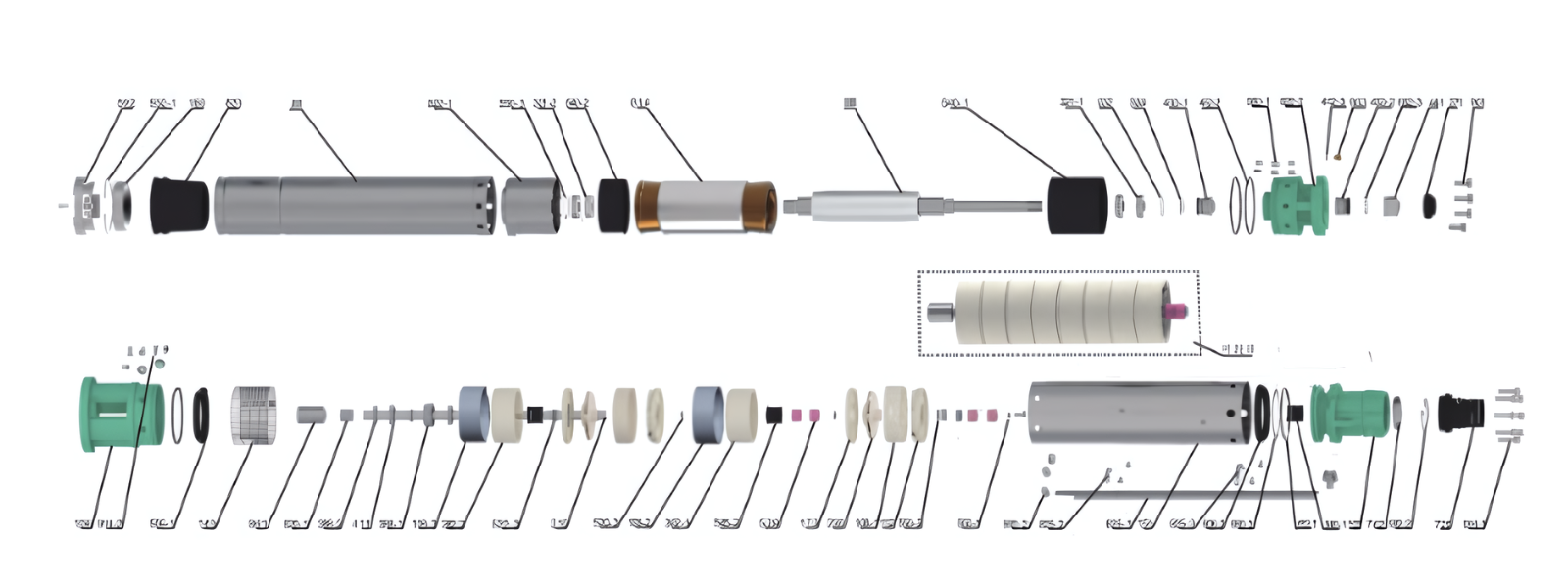

Components & Material:

| No. | Part name | No. | Part name | No. | Part name |

| 106 | Inlet joint | 412-2 | O-ring | 592 | Base |

| 107 | Delivery chamber | 412-3 | 0-ring | 720 | Outlet joint |

| 108-1 | Guide vane ring | 433-1 | Mechanical seal | 742 | Bonnet |

| 108-2 | 1 Intermediate support seat ring | 433-2 | Mechanical seal | 811 | Casing |

| 108-3 | Lower support seat ring | 441 | Stainless steel sleeve | 814 | Stator core with winding |

| 112 | Flow deflector | 506-1 | Inlet joint ring | 818 | Rotor |

| 143 | Net cover | 506-2 | Delivery chamber ring | 822-1 | Lower bearing block |

| 151 | Upper sleeve | 520-1 | Spacer bush | 822-2 | Ol chamber |

| 160 | Bottom cover | 520-2 | Spacer bush | 823 | Pressure regulating film |

| 173 | Guide vane cover plate | 520-3 | Spacer bush | 825-1 | Cable pressing plate |

| 210 | Pump shaft | 529 | Shaft sleeve | 825-2 | Small pressing plate |

| 230 | Impeller | 540-1 | Upper spacer sleeve | 825-3 | Large pressing plate |

| 231 | Impeller string | 540-2 | Lower spacer sleeve | 861 | Coupling |

| 321-1 | Deep groove balt bearing | 545-1 | Lower rubber bearing | 901 | Outer hexagon flat screw |

| 321-2 | Angular contact ball bearing | 545-2 | Upper rubber bearing | 903 | Vent cock |

| 382-1 | Intermediate support seat | 550-1 | Pump shaft gasket | 914-1 | Hexagon socket head cap screw |

| 382-2 | Lower support seat | 550-2 | Adjusting washer | 914-2 | Hexagon. socket countersunk head screw |

| 271 | Sand shaking sleeve | 550-3 | Adjusting washer | 932-1 | Retaining ring |

| 388-1 | Arresting disc fixing sleeve | 552 | Wave spring | 932-2 | Retaining ring |

| 388-2 | Arresting disc | 554 | Flat washer | 932-3 | Circlip for shaft |

| 411 | Friction pad | 560-1 | Locating sleeve | 560-2 | Locating pin |

| 412-1 | 0-ring |

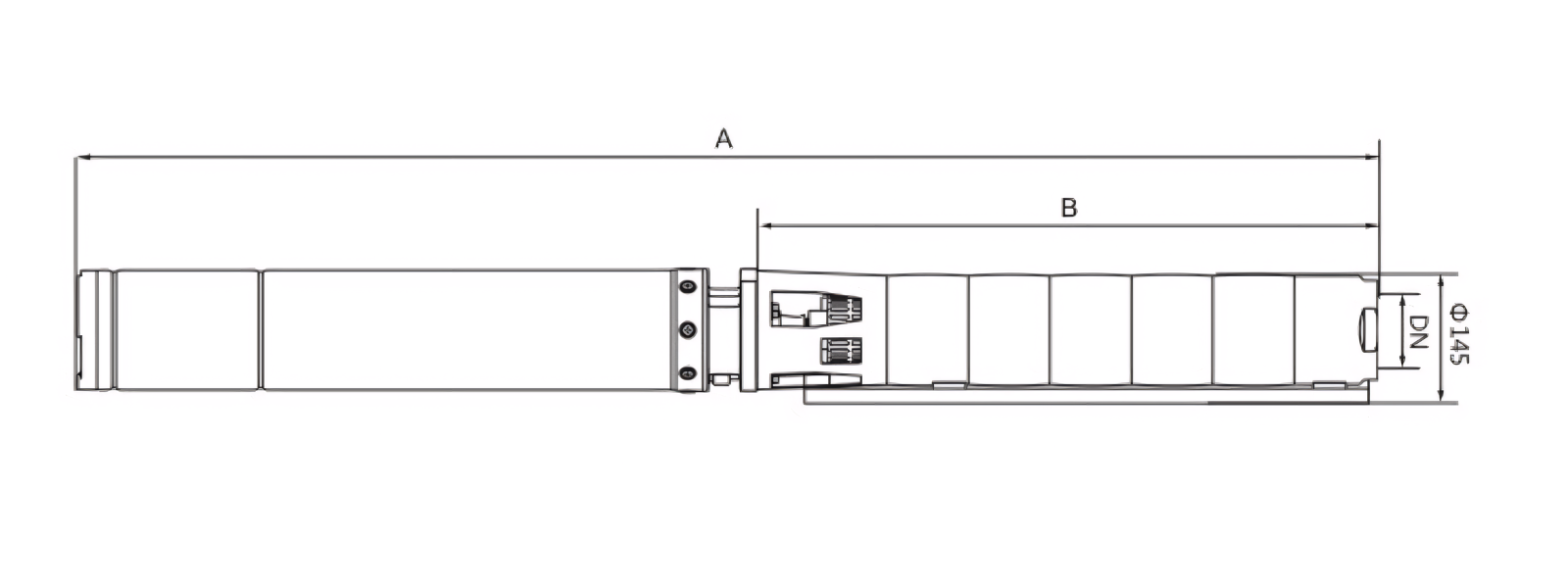

Dimensions & Weight:

| Model | Pipe Connection (DN) | Dim. (mm) | N.W.(kg) | ||

| Three-phase | B | A Three-phase | Body(kg) | Motor(kg) | |

| 6SE10/10 | G3 | 785 | 1586 | 18.50 | 40.00 |

| 6SE10/14 | 935 | 1801 | 22.00 | 45.00 | |

| 6SE10/16 | 1080 | 2006 | 24.60 | 50.00 | |

| 65E10/20 | 1235 | 2231 | 28.00 | 58.00 | |

| 6SE10/22 | 1315 | 2369 | 30.10 | 64.00 | |

| 65E10/26 | 1615 | 270B | 36.50 | 67.00 | |

| 6SE18/6 | 676 | 1478 | 16.00 | 40.00 | |

| 65E18/9 | 815 | 1677 | 20.00 | 45.00 | |

| 6SE18/11 | 909 | 1836 | 21.50 | 50.00 | |

| 65E18/13 | 1002 | 1999 | 23.00 | 58.00 | |

| 65E18/15 | 1095 | 2152 | 25.00 | 64.00 | |

| 65E18/18 | 1235 | 2332 | 28.00 | 67.00 | |

| 65E30/5 | 665 | 1467 | 16.50 | 40.00 | |

| 65E30/7 | 773 | 1635 | 18.10 | 45.00 | |

| 6SE 30/9 | 880 | 1807 | 20.00 | 50.00 | |

| 65E30/10 | 935 | 1932 | 21.00 | 58.00 | |

| 65E30/11 | 988 | 2045 | 22.30 | 64.00 | |

| 65E30/13 | 1096 | 2193 | 24.10 | 67.00 | |

| 65E45/5 | 730 | 1592 | 18.00 | 45.00 | |

| 65E45/6 | 797 | 1724 | 19.00 | 50.00 | |

| 65E45/7 | 864 | 1861 | 20.50 | 58.00 | |

| 65E45/8 | 930 | 1987 | 22.00 | 64.00 | |

| 65E45/9 | 1059 | 2156 | 23.00 | 67.00 | |

| Model | Pipe Connection (DN) | Dim. (mm) | N.W.(kg) | ||

| Three-phase | B | A Three-phase | Body(kg) | Motor(kg) | |

| 6SE10/10K2 | G3 | 910 | 1670 | 18.5 | 31.5 |

| 6SE10/14K2 | 1070 | 1890 | 22.5 | 36.8 | |

| 6SE10/16K2 | 1210 | 2090 | 24.6 | 42 | |

| 6SE10/20K2 | 1370 | 2250 | 27.5 | 50 | |

| 6SE10/22K2 | 1450 | 2450 | 30.1 | 56 | |

| 6SE10/26K2 | 1750 | 2800 | 36.5 | 60 | |

| 6SE18/6K2 | 800 | 1560 | 16 | 31.3 | |

| 6SE18/9K2 | 950 | 1770 | 20 | 36.8 | |

| 6SE18/11K2 | 1040 | 1920 | 21.5 | 42 | |

| 6SE18/13K2 | 1130 | 2010 | 23 | 50 | |

| 65E18/15K2 | 1230 | 2230 | 25 | 56 | |

| 6SE18/18K2 | 1370 | 2420 | 28 | 60 | |

| 6SE30/5K2 | 800 | 1560 | 16.5 | 31.3 | |

| 6SE30/7K2 | 910 | 1730 | 18.1 | 36.8 | |

| 6SE30/9K2 | 1020 | 1900 | 20.5 | 42 | |

| 6SE30/10K2 | 1070 | 1950 | 21.4 | 50 | |

| 65E30/11K2 | 1130 | 2130 | 22.3 | 56 | |

| 6SE30/13K2 | 1230 | 2280 | 25.5 | 60 | |

| 6SE45/5K2 | 860 | 1680 | 18 | 36.8 | |

| 6SE45/6K2 | 930 | 1810 | 19 | 42 | |

| 65E45/7K2 | 1000 | 1880 | 20.5 | 50 | |

| 65E45/8K2 | 1070 | 2070 | 22 | 56 | |

| 6SE45/9K2 | 1190 | 2240 | 23 | 60 | |

Application:

- Agricultural Irrigation: Ideal for large-scale farming, this pump provides the high volume of water necessary for irrigation, ensuring consistent crop watering and promoting healthy agricultural yields.

- Industrial Water Supply: In industrial settings, it supports processes requiring substantial water flow, such as cooling, processing, and cleaning operations.

- Municipal Water Systems: This pump can be employed in municipal water systems for water distribution, helping to maintain a steady supply to communities.

- Mining Operations: It supports mining activities, supplying water for mineral processing, dust control, and other essential mining processes.

- Golf Courses and Landscaping: The high flow rate is perfect for maintaining golf courses and large-scale landscaping projects, ensuring lush, well-watered greenery.

- Residential Water Supply: For large properties or homes with high water demand, this pump provides an efficient and reliable water source.

- Environmental Water Management: It can be used in environmental projects, like wetland restoration or habitat conservation, to regulate water levels and support ecosystem health.

Application Limits:

- Temperature Tolerance: Operates effectively in ambient temperatures up to 40℃, ensuring reliability in warmer climates.

- Sand Resistance: Capable of handling up to 100 grams of sand per cubic meter, this pump maintains efficiency and longevity even in sandy water conditions.

- Chemical Resistance: Tolerates hydrogen sulfide content up to 1.5 mg/L and chloride ion levels up to 400 mg/L, making it suitable for areas with slightly contaminated water sources.

- pH Range Adaptability: Functions optimally in water with a pH range from 6.5 to 8.5, ensuring compatibility with a wide range of natural water acidity levels.

- Depth Capability: Designed to operate at depths up to 70 meters below the static water table, making it ideal for deep well applications.

FAQ:

1.What is the maximum depth at which the 6SE(K2) can operate effectively?

The 6SE(K2) is designed to function efficiently at depths up to 70 meters below the static water table, making it suitable for deep well applications.

2.Can this pump handle sandy water?

Yes, the pump can process water containing up to 100 grams of sand per cubic meter, maintaining its efficiency and durability even in sandy conditions.

3.Is the 6SE(K2) suitable for use in areas with high ambient temperatures?

Absolutely, this pump is designed to operate in ambient temperatures up to 40℃, ensuring reliable performance in warmer climates.

4.What range of water pH levels can the 6SE(K2) handle?

The pump operates effectively in water with a pH range from 6.5 to 8.5, accommodating a variety of natural water conditions.

5.Can the pump handle water with hydrogen sulfide and chloride ions?

Yes, it’s capable of handling water with hydrogen sulfide content up to 1.5 mg/L and chloride ion content up to 400 mg/L, making it versatile for slightly contaminated water sources.

6.What are the main applications for the 6SE(K2) pump?

This pump is ideal for a wide range of applications, including agricultural irrigation, industrial water supply, municipal water systems, mining operations, golf course and large-scale landscaping maintenance, residential water supply, and environmental water management projects.