4 Inch Deep Well Pumps 4TY 106GPM

Introducing our 4-Inch Deep Well Pump, model 4TY, a powerful and reliable solution for your water extraction needs. Capable of delivering a remarkable 106 gallons per minute, this pump is designed to operate efficiently in deep well applications. Its 4-inch size ensures compatibility with most well diameters, offering a seamless fit and easy installation. Constructed with durability in mind, it withstands demanding conditions, ensuring long-term operation. Whether for agricultural irrigation, residential water supply, or industrial use, the 4TY model offers consistent performance and superior water flow, making it an ideal choice for those requiring a high-capacity, robust deep well pump.

Features:

- IP 44 Controller Housing: Designed for outdoor use, the controller housing is robust and weather-resistant, ensuring reliable performance in diverse environmental conditions.

- MPPT Technology: Maximizes the power utilization from photovoltaic modules, ensuring that every ray of sunlight is efficiently converted into usable energy.

- LED Display Panel: An easy-to-operate interface that allows users to effortlessly monitor the working status of the pump, including power, voltage, and RPM.

- VFD Technology: Automatically adjusts operation according to actual needs. This feature helps maintain constant pressure, contributing to significant energy savings and optimal performance.

- Soft Start Mechanism: Ensures there is no impact current at start-up, prolonging the service life of the pump by reducing mechanical stress.

- Comprehensive Protection Functions: Equipped with overcurrent, overvoltage, locked rotor, phase failure, and dry run protection functions to safeguard the system under various challenging conditions.

- Float Control: Available for automatic operation, making the system user-friendly and reducing the need for manual intervention.

- AC/DC Automatic or Manual Switching: Available for models with an input power P1 above 1.3KW, offering flexibility in power sources and operational modes.

- Energy-Efficient Design: Our pump is engineered for maximum energy efficiency, reducing electricity costs and contributing to a greener environment.

- Advanced Diagnostics: Integrated diagnostic tools detect and alert users to potential issues before they become problems, ensuring uninterrupted operation and reducing maintenance costs.

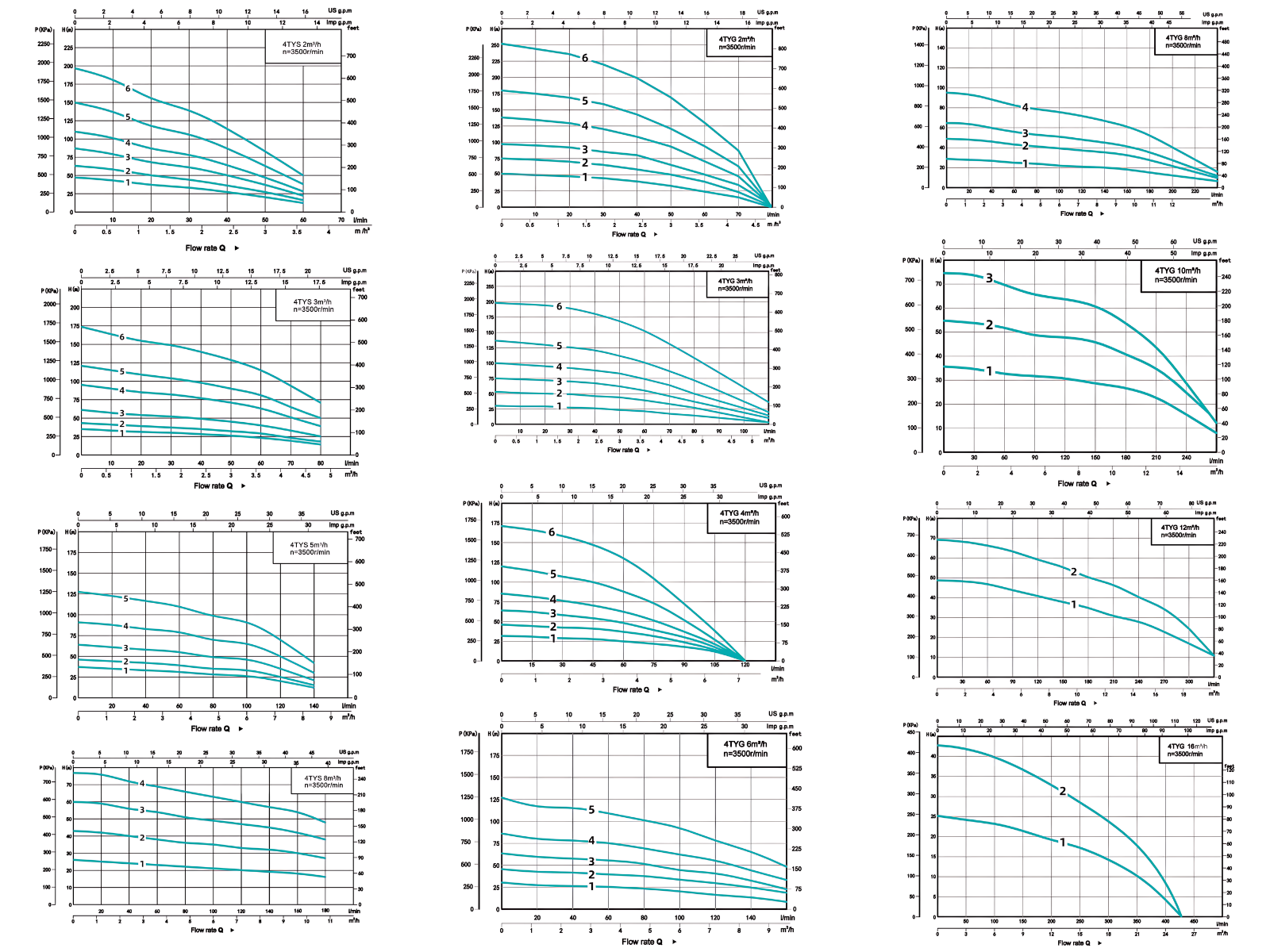

Performance Curve

| No. | Model | Input Power P1 | Best DC Range | Max.Flow | Max.Head | Flow | Recommend Solar Pannel Power(W) | ||||||||

| m3/h | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.2 | |||||||

| (W) | Voc(V) | m”/h | m | l/min | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | |||

| 1 | 4TYG 5-52-72-0.9 | 0.9 | 60-90 | 5 | 52 | H(m) | 52 | 50 | 48 | 45 | 40 | 33 3 | 24 | 15 | 21 200 |

| 2 | 4TYG 5-75-96-11 | 1.1 | 100-140 | 5 | 75 | 75 | 73 | 70 | 65 | 58 | 50 | 39 | 23 | 21400 | |

| 3 | 4TYG 5-94-120-13 | 1.3 | 120-160 | 5 | 94 | 94 | 92 | 89 | 82 | 77 | 62 | 47 | 31 | 21700 | |

| 4 | 4TYG5-138-310-2A/D | 2.2 | 300-405 | 5 | 138 | 138 | 134 | 129 | 120 | 108 | 93 | 70 | 47 | 22800 | |

| 5 | 4TYG5-180-310-2.6A/D | 2.6 | 300-405 | 5 | 180 | 180 | 175 | 169 | 159 | 143 | 121 | 94 | 63 | 23300 | |

| 6 | 4TYG5-258-310-3.4A/D | 3.4 | 300-405 | 5 | 258 | 258 | 250 | 242 | 226 | 205 | 175 | 136 | 93 | 24400 | |

| No. | Model | Input Power P1 | Best DC Range | Max.Flow | Max.Head | Flow | Recommend Solar Pannel Power(W) | ||||||||||

| m3/h | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.2 | 4.8 | 5.4 | |||||||

| (W) | Voc(V) | m”/h | m | l/min | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | |||

| 1 | 4TYG6.5-31-72-0.75 | 0.75 | 60-90 | 6.5 | 31 | H(m) | 31 | 30.1 | 30 | 28 | 27 | 24 | 18 | 18 | 15 | 12 | 21000 |

| 2 | 4TYG6.5-53-96-11 | 1.1 | 100-140 | 6.5 | 53 | 51.2 | 51 | 50 | 49 | 46 | 44 | 33 | 33 | 27 | 19 | 21400 | |

| 3 | 4TYG6.5-75-120-13 | 1.3 | 120-160 | 6.5 | 75 | 75 | 72.2 | 72 ? | 70 | 67 | 62 | 46 | 46 | 37 | 28 | 21700 | |

| 4 | 4TYG65-98-310-2A/D | 2.2 | 300-405 | 6.5 | 98 | 95 | 94 | 93 | 90 | 86 | 81 | 62 | 62 | 48 | 33 | 22300 | |

| 5 | 4TYG6.5-132-310-2.6A/D | 2.6 | 300-405 | 6.5 | 132 | 127 | 126 | 125 | 121 | 116 | 107 | 82 | 82 | 67 | 50 | 23300 | |

| 6 | 4TYG65-195-310-34A/D | 3.4 | 300-405 | 6.5 | 195 | 194 | 193 | 191 | 186 | 177 | 165 | 128 | 128 | 105 | 81 | 24400 | |

| No. | Model | Input Power P1 | Best DC Range | Max.Flow | Max.Head | Flow | Recommend Solar Pannel Power(W) | |||||||||

| m3/h | 0 | 0.9 | 1.8 | 2.7 | 3.6 | 4.5 | 5.4 | 6.3 | 7.2 | |||||||

| (W) | Voc(V) | m”/h | m | l/min | 0 | 15 | 30 | 45 | 60 | 75 | 90 | 105 | 120 | |||

| 1 | 4TYG 8-30-72-0.75 | 0.75 | 60-90 | 8 | 30 | H(m) | 30 | 28 | 27 | 26 | 23 | 20 | 16 | 10 | 3 | 21000 |

| 2 | 4TYG 8-42-96-1.1 | 1.1 | 100-140 | 8 | 42 | 42 | 39 | 38 | 37 | 33 | 29 | 23 | 16 | 7 | 21400 | |

| 3 | 4TYG 8-64-120-1.3 | 1.3 | 120-1 60 | 8 | 64 | 64 | 61 | 58 | 56 | 51 | 45 | 36 | 25 | 12 | 21700 | |

| 4 | 4TYG 8-85-310-2A/D | 2.2 | 300-405 | 8 | 85 | 85 | 81 | 79 | 75 | 69 | 60 | 49 | 35 | 17 | 22300 | |

| 5 | 4TYG8-117-310-2.6A/D | 2.6 | 300-405 | 8 | 117 | 117 | 111 | 108 | 102 | 94 | 83 | 67 | 48 | 26 | 23300 | |

| 6 | 4TYG8-171-310-3.4A/D | 3.4 | 300-405 | 8 | 171 | 171 | 163 | 158 | 151 | 139 | 124 | 101 | 74 | 38 | 24400 | |

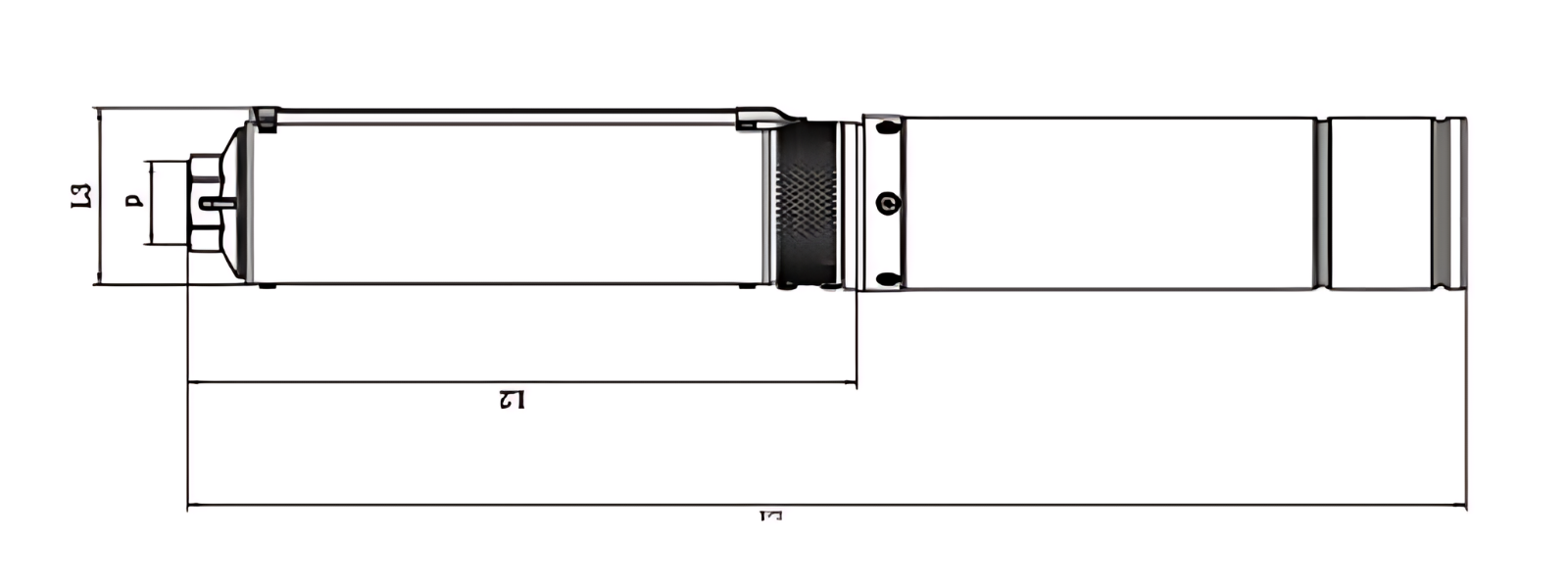

| Model | P-Pipe Connection (Inch) | L1 (mm) | L2 (mm) | L3 (mm) | G.W.(KG) | Package Size (mm) | PV Panel Connection |

|---|---|---|---|---|---|---|---|

| 4TYG5-52-72-0.9 | G1-1/4 | 610 | 286.5 | 102 | 14.0 | 1030×255×125 | 2S2P |

| 4TYG5-75-96-1.1 | G1-1/4 | 665 | 336.5 | 102 | 15.0 | 1090×255×125 | 3S2P |

| 4TYG5-94-120-1.3 | G1-1/4 | 723 | 387.5 | 102 | 15.0 | 1130×255×125 | 3S2P |

| 4TYG5-138-310-2-A/D | G1-1/4 | 828 | 481.5 | 102 | 24.0 | 1370×290×195 | 8S |

| 4TYG5-180-310-2.6-A/D | G1-1/4 | 938 | 581.5 | 102 | 25.0 | 1480×290×195 | 9S |

| 4TYG5-258-310-3.4-A/D | G1-1/4 | 1170 | 790.5 | 102 | 29.0 | 1710×290×195 | 7S2P |

| 4TYG6.5-31-72-0.75 | G1-1/4 | 561 | 237.5 | 102 | 14.0 | 970×255×125 | 2S2P |

| 4TYG6.5-53-96-1.1 | G1-1/4 | 618 | 289.5 | 102 | 14.0 | 1030×255×125 | 3S2P |

| 4TYG6.5-75-120-1.3 | G1-1/4 | 677 | 341.5 | 102 | 15.0 | 1090×255×125 | 3S2P |

| 4TYG6.5-98-310-2-A/D | G1-1/4 | 740 | 393.5 | 102 | 23.0 | 1280×290×195 | 8S |

| 4TYG6.5-132-310-2.6-A/D | G1-1/4 | 828 | 471.5 | 102 | 24.0 | 1370×290×195 | 9S |

| 4TYG6.5-195-310-3.4-A/D | G1-1/4 | 1007 | 627.5 | 102 | 27.0 | 1550×290×195 | 7S2P |

| 4TYG8-30-72-0.75 | G1-1/4 | 570 | 246.5 | 102 | 14.0 | 990×255×125 | 2S2P |

| 4TYG8-42-96-1.1 | G1-1/4 | 604 | 275.5 | 102 | 14.0 | 1030×255×125 | 3S2P |

| 4TYG8-64-120-1.3 | G1-1/4 | 669 | 333.5 | 102 | 15.0 | 1090×255×125 | 3S2P |

| 4TYG8-95-310-2-A/D | G1-1/4 | 738 | 391.5 | 102 | 23.0 | 1280×290×195 | 8S |

| 4TYG8-117-310-2.6-A/D | G1-1/4 | 835 | 478.5 | 102 | 24.0 | 1370×290×195 | 9S |

| 4TYG8-171-310-3.4-A/D | G1-1/4 | 1073 | 693.5 | 102 | 27.5 | 1610×290×195 | 7S2P |

| 4TYG12-32-96-1.1 | G1-1/2 | 580 | 251.5 | 102 | 14.0 | 990×255×125 | 3S2P |

| 4TYG12-42-120-1.2 | G1-1/2 | 618 | 282.5 | 102 | 14.0 | 1030×255×125 | 3S2P |

| 4TYG12-64-310-2-A/D | G1-1/2 | 702 | 355.5 | 102 | 22.0 | 1240×290×195 | 8S |

| 4TYG12-86-310-2.6-A/D | G1-1/2 | 778 | 421.5 | 102 | 23.0 | 1320×290×195 | 9S |

| 4TYG12-128-310-3.4-A/D | G1-1/2 | 967 | 587.5 | 102 | 26.0 | 1510×290×195 | 7S2P |

| 4TYG15-28-120-1.1 | G2 | 609 | 273.5 | 102 | 14.0 | 1030×255×125 | 3S2P |

| 4TYG15-46-310-2-A/D | G2 | 696 | 349.5 | 102 | 22.0 | 1240×290×195 | 8S |

| 4TYG15-65-310-2.6-A/D | G2 | 782 | 425.5 | 102 | 23.5 | 1320×290×195 | 9S |

| 4TYG15-94-310-3.4-A/D | G2 | 954 | 574.5 | 102 | 26.0 | 1490×290×195 | 7S2P |

| 4TYG17.5-36-310-2-A/D | G2 | 659 | 312.5 | 102 | 21.5 | 1200×290×195 | 8S |

| 4TYG17.5-54-310-2.6-A/D | G2 | 744 | 387.5 | 102 | 23.0 | 1280×290×195 | 9S |

| 4TYG17.5-74-310-3.4-A/D | G2 | 878 | 498.5 | 102 | 25.0 | 1420×290×195 | 7S2P |

| 4TYG22-48-310-2.6-A/D | G2 | 815 | 458.5 | 102 | 24.0 | 1350×290×195 | 9S |

| 4TYG22-68-310-3.4-A/D | G2 | 935 | 555.5 | 102 | 26.0 | 1470×290×195 | 7S2P |

| 4TYG25-26-310-2.6-A/D | G2 | 793 | 436.5 | 102 | 23.0 | 1330×290×195 | 9S |

| 4TYG25-43-310-3.4-A/D | G2 | 968 | 588.5 | 102 | 26.5 | 1510×290×195 | 7S2P |

| 4TYS4.5-52-72-0.9 | G1-1/4 | 577 | 285.5 | 102 | 14.0 | 990×255×125 | 2S2P |

| 4TYS4.5-70-96-1.1 | G1-1/4 | 624 | 290.5 | 102 | 15.0 | 1030×255×125 | 3S2P |

| 4TYS4.5-85-120-1.3 | G1-1/4 | 694 | 297.5 | 102 | 15.5 | 1090×255×125 | 3S2P |

| 4TYS4.5-125-310-2-A/D | G1-1/4 | 768 | 308.5 | 102 | 25.5 | 1300×290×195 | 8S |

| 4TYS4.5-170-310-2.6-A/D | G1-1/4 | 883 | 318.5 | 102 | 27.5 | 1410×290×195 | 9S |

| 4TYS4.5-230-310-3.4-A/D | G1-1/4 | 1032 | 541.5 | 102 | 30.0 | 1560×290×195 | 7S2P |

| 4TYS6-35-72–0.75 | G1-1/4 | 535 | 285.5 | 102 | 14.0 | 950×255×125 | 2S2P |

| 4TYS6-43-96-1.1 | G1-1/4 | 561 | 290.5 | 102 | 14.0 | 970×255×125 | 3S2P |

| 4TYS6-61-120-1.3 | G1-1/4 | 610 | 297.5 | 102 | 15.0 | 1030×255×125 | 3S2P |

| 4TYS6-95-310-2-A/D | G1-1/4 | 705 | 308.5 | 102 | 24.5 | 1230×290×195 | 8S |

| 4TYS6-121-310-2.6-A/D | G1-1/4 | 778 | 318.5 | 102 | 25.5 | 1300×290×195 | 9S |

| 4TYS6-174-310-3.4-A/D | G1-1/4 | 927 | 341.5 | 102 | 30.0 | 1450×290×195 | 7S2P |

| 4TYS9.5-37-96-1.1 | G1-1/2 | 553 | 290.5 | 102 | 14.0 | 970×255×125 | 3S2P |

| 4TYS9.5-46-120-1.3 | G1-1/2 | 583 | 297.5 | 102 | 14.5 | 990×255×125 | 3S2P |

| 4TYS9.5-64-310-2-A/D | G1-1/2 | 642 | 308.5 | 102 | 24.0 | 1170×290×195 | 8S |

| 4TYS9.5-91-310-2.6-A/D | G1-1/2 | 724 | 318.5 | 102 | 24.5 | 1250×290×195 | 9S |

| 4TYS9.5-128-310-3.4-A/D | G1-1/2 | 843 | 341.5 | 102 | 28.5 | 1370×290×195 | 7S2P |

| 4TYS16-26-120-1.3 | G2 | 589 | 297.5 | 102 | 15.0 | 990×255×125 | 3S2P |

| 4TYS16-43-310-2-A/D | G2 | 684 | 308.5 | 102 | 25.0 | 1210×290×195 | 8S |

| 4TYS16-60-310-2.6-A/D | G2 | 778 | 318.5 | 102 | 26.5 | 1300×290×195 | 9S |

| 4TYS16-77-310-3.4-A/D | G2 | 885 | 341.5 | 102 | 30.0 | 1410×290×195 | 7S2P |

Components & Material

| No. | Part name |

|---|---|

| 106 | Inlet joint |

| 107 | Delivery chamber |

| 143 | Net cover |

| 151 | Sleeve |

| 160-1 | Bottom cover |

| 160-2 | Cover plate |

| 171 | Guide vane |

| 173 | Guide vane cover plate |

| 210 | Pump shaft |

| 230 | Impeller |

| 231 | Impeller string |

| 271 | Sand prevention cover |

| 321-1 | Deep groove ball bearing |

| 321-2 | Deep groove ball bearing |

| 382 | Bearing seat |

| 411 | Wear washer |

| 412-1 | O-ring |

| 412-2 | O-ring |

| 412-3 | O-ring |

| 433 | Mechanical seal |

| 440-1 | Sand prevention seat |

| 440-2 | Sand prevention pad |

| 520 | Spacer bush |

| 529 | Shaft sleeve |

| 545 | Rubber bearing |

| 550-1 | Adjusting washer |

| 550-2 | Washer |

| 554 | Washer |

| 560 | Location pin |

| 742 | Bonnet |

| 752 | Valve set |

| 814 | Stator |

| 818 | Rotor |

| 822-1 | Oil chamber |

| 822-2 | Bottom bearing seat |

| 823 | Regulating membrane |

| 825-1 | Clamp |

| 825-2 | Cable clamp |

| 825-3 | Clamp |

| 827 | Top spacer sleeve |

| 904 | Air release cock |

| 914 | Hexagon socket set screw |

| 932 | Spacer sleeve |

| 950 | Wave spring |

| 955 | Dust prevention cover |

Operating Conditions

- Temperature Constraints:The maximum ambient temperature must not exceed 40°C, requiring the pump and its components to be designed and selected to withstand this temperature range without compromising performance or reliability.

- Sand Content Limitation:The pump must be capable of handling a maximum sand content of 100 g/m³ in the pumped fluid. This means the pump design, materials, and construction need to be optimized for efficient sand handling and separation to prevent excessive wear and damage to critical components.

- Water Chemistry Considerations:The water being pumped contains moderate levels of hydrogen sulfide (up to 1.5 mg/L) and chloride ions (up to 400 mg/L), indicating a moderately corrosive environment. The pH range of 6.5 to 8.5 is relatively neutral, but the corrosive nature of the water still necessitates the use of corrosion-resistant materials for pump components in contact with the fluid.

- Depth and Pressure Requirements:The pump must be capable of operating at a maximum depth of 70 m below the static water table, which translates to a hydrostatic pressure of approximately 7 bar. The pump design and construction, including the housing, seals, and bearings, need to be robust enough to withstand this high-pressure environment without leakage or structural failure.

Application

- Groundwater Extraction: These pumps are designed for the extraction of groundwater from deep wells, typically ranging from 40 to 70 meters in depth.

- Reliable Operation: The robust construction and sand-handling capabilities of the 4TY series make them well-suited for continuous operation in challenging downhole environments.

- Corrosion Resistance: The pump components are engineered to withstand moderately corrosive groundwater containing up to 1.5 mg/L of hydrogen sulfide and 400 mg/L of chloride ions.

- Abrasion Tolerance: The pump’s design and materials can handle the presence of up to 100 g/m³ of sand in the pumped fluid, minimizing wear and ensuring extended service life.

- High-Pressure Capability: The pump’s ability to operate at depths of up to 70 meters below the static water table allows it to handle the corresponding hydrostatic pressures of approximately 7 bar.

- Efficient Hydraulic Performance: The optimized impeller and volute design of the 4TY series deliver high efficiency and flow rates up to 106 GPM.

- Versatile Installation: These pumps can be integrated into a variety of well casing configurations and can be easily installed and serviced.

- Compact Design: The 4-inch diameter of the 4TY series allows for easy deployment in narrow-diameter wells, making them a suitable choice for many residential and light commercial applications.

- Energy Efficiency: The pump’s hydraulic design and motor efficiency contribute to reduced energy consumption, lowering operating costs over the long term.

- Regulatory Compliance: The 4TY series meets relevant industry standards and regulations, ensuring safety and reliability in deep well water extraction applications.

FAQ

1.What is the maximum depth these pumps can reach?

These 4 Inch Deep Well Pumps are designed to reach depths of up to [specify maximum depth] feet.

2.What is the flow rate of the 4TY 106GPM pumps?

The 4TY 106GPM pumps have a flow rate of 106 gallons per minute, ensuring efficient water delivery.

3.Are these pumps suitable for residential use?

Yes, these pumps are commonly used for residential applications such as supplying water to homes from deep wells.

4.Do these pumps require frequent maintenance?

With proper installation and regular upkeep, these pumps typically require minimal maintenance, ensuring reliable performance over time.

5.Can these pumps handle varying water conditions?

Yes, these pumps are built to handle various water conditions, including sandy or muddy environments, ensuring consistent operation.

6.What is the power source required for these pumps?

These 4 Inch Deep Well Pumps typically require a standard electrical power source, making them easy to install and use in most locations.