4 Inch Deep Well Pumps 4SS 62GPM

The 4 Inch Deep Well Pump 4SS, with its robust 62GPM capacity, is an engineering marvel designed for efficient and reliable performance. Crafted for deep well applications, this pump is perfect for agricultural, residential, and commercial needs, offering a consistent and powerful water supply. Its 4-inch diameter makes it ideal for fitting into smaller well casings, while the impressive 62 gallons per minute output ensures ample water flow. The pump’s stainless steel construction guarantees durability and resistance against corrosion, ensuring a long service life even in challenging environments. With easy installation and low maintenance, this pump is a cost-effective solution for your water extraction needs, providing not just functionality but also peace of mind.

Features:

- Edible Oil Filled Motor with Pressure Regulating Membrane: This unique feature ensures stable and reliable operation. The use of edible oil not only provides excellent lubrication but also makes it environmentally friendly. The pressure regulating membrane contributes to the consistent performance under varying water pressures.

- Single Phase Motor with Integrated Start Box: The motor comes equipped with a start box that includes a built-in capacitor and a current mode thermal protector. This design enhances the pump’s safety and reliability, while also making maintenance and replacement of components more convenient.

- Corrosion-Resistant Stainless Steel Pump Head: The pump head is constructed from high-quality stainless steel, offering effective protection against corrosion and abrasive wear. This ensures a longer lifespan and consistent performance in different water qualities.

- Versatile Installation Options: Designed for installation in 4-inch or larger boreholes, this pump offers flexibility for a range of deep well applications, accommodating varying well sizes and depths.

- High-Flow Output: With its powerful 62GPM capacity, the pump can handle significant water extraction requirements, making it suitable for both heavy-duty and everyday applications.

- Energy Efficient Design: The pump is designed for maximum efficiency, reducing energy consumption while maintaining a high output, resulting in lower operational costs over time.

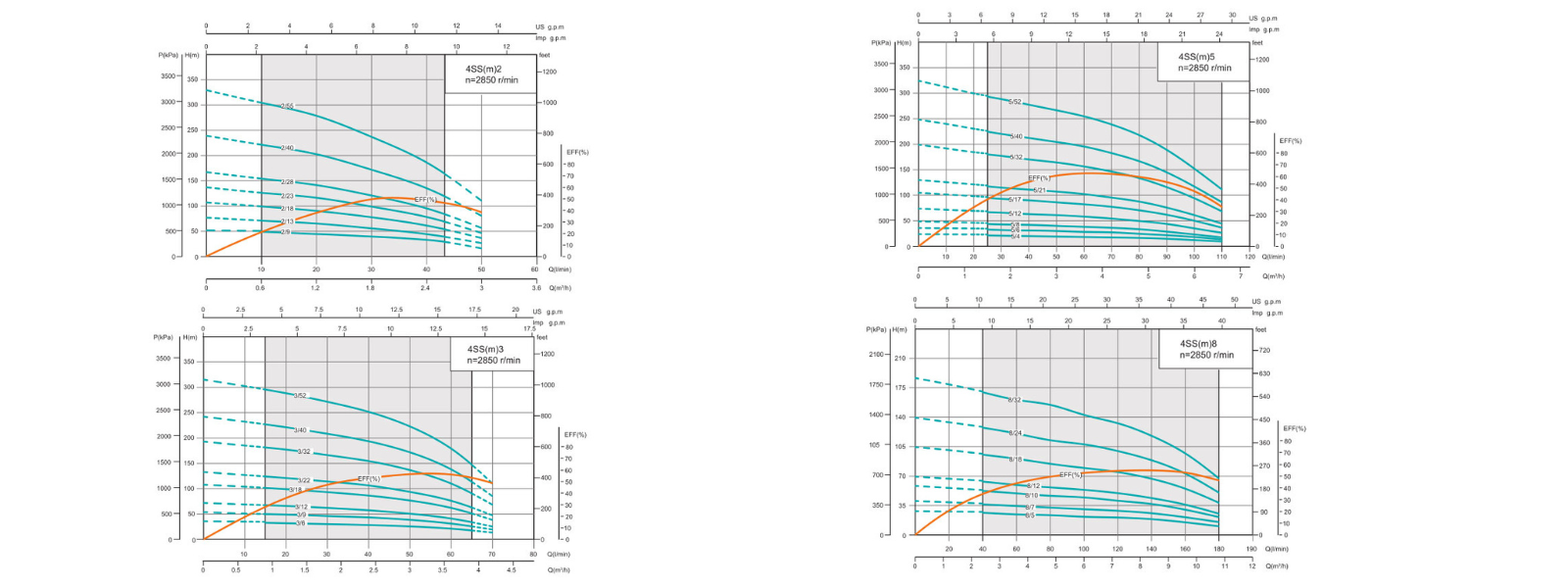

Performance Curve

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||

| Single-Phase | Three-Phase | kW | HP | Single-Phase | Three-Phase | m³/h | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | |

| 220V | 380V | 220V | 380V | l/min | 0 | 10 | 20 | 30 | 40 | 50 | |||

| 4SSm2/9 | – | 0.37 | 0.5 | 3.3 | – |

H(m) |

54 | 50 | 46 | 39 | 30 | 18 | 50-26 |

| 4SSm2/13 | – | 0.55 | 0.75 | 4.6 | – | 78 | 72 | 66 | 56 | 44 | 26 | 72-38 | |

| 4SSm2/18 | 4SS2/18 | 0.75 | 1 | 6 | 2.6 | 108 | 100 | 91 | 78 | 61 | 36 | 100-53 | |

| 4SSm2/23 | 4SS2/23 | 1.1 | 1.5 | 8.4 | 3.4 | 138 | 127 | 117 | 99 | 78 | 46 | 127-68 | |

| 4SSm2/28 | 4SS2/28 | 1.5 | 2 | 10.9 | 4.4 | 168 | 155 | 144 | 121 | 95 | 56 | 155-83 | |

| 4SSm2/40 | 4SS2/40 | 2.2 | 3 | 15.8 | 6.2 | 240 | 222 | 209 | 172 | 135 | 80 | 222-117 | |

| 4SSm2/55 | 4SS2/55 | 3 | 4 | 21 | 8.3 | 330 | 305 | 279 | 237 | 186 | 119 | 305-163 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||

| Single-Phase | Three-Phase | kW | HP | Single-Phase | Three-Phase | m³/h | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.2 | |

| 220V | 380V | 220V | 380V | l/min | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | |||

| 4SSm3/6 | – | 0.37 | 0.5 | 3.3 | – |

H(m) |

37 | 35 | 33 | 31 | 29 | 26 | 21 | 13 | 34-17 |

| 4SSm3/9 | – | 0.55 | 0.75 | 4.6 | – | 55 | 52 | 50 | 47 | 44 | 39 | 31 | 19 | 51-25 | |

| 4SSm3/12 | 4SS3/12 | 0.75 | 1 | 6 | 2.6 | 73 | 70 | 67 | 63 | 58 | 51 | 41 | 25 | 68-33 | |

| 4SSm3/18 | 4SS3/18 | 1.1 | 1.5 | 8.4 | 3.4 | 109 | 105 | 100 | 94 | 87 | 77 | 62 | 38 | 102-51 | |

| 4SSm3/22 | 4SS3/22 | 1.5 | 2 | 10.9 | 4.4 | 134 | 128 | 122 | 115 | 107 | 94 | 76 | 47 | 125-62 | |

| 4SSm3/32 | 4SS3/32 | 2.2 | 3 | 15.8 | 6.2 | 194 | 186 | 178 | 167 | 155 | 137 | 110 | 68 | 182-90 | |

| 4SSm3/40 | 4SS3/40 | 3 | 4 | 21 | 8.3 | 243 | 233 | 222 | 209 | 194 | 172 | 138 | 85 | 227-113 | |

| 4SSm3/52 | 4SS3/52 | 4 | 5.5 | 27 | 10.8 | 316 | 303 | 289 | 272 | 252 | 223 | 179 | 110 | 296-147 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||||||

| Single-Phase | Three-Phase | kW | HP | Single-Phase | Three-Phase | m³/h | 0 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.2 | 4.8 | 5.4 | 6 | 6.6 | |

| 220V | 380V | 220V | 380V | l/min | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | |||

| 4SSm5/4 | – | 0.37 | 0.5 | 3.3 | – | H(m) | 25 | 24 | 23 | 22 | 21 | 20 | 19 | 18 | 17 | 15 | 12 | 9 | 9–23 |

| 4SSm5/6 | – | 0.55 | 0.75 | 4.6 | – | 37 | 36 | 35 | 33 | 32 | 31 | 29 | 28 | 25 | 22 | 18 | 13 | 34-13 | |

| 4SSm5/8 | 4SS5/8 | 0.75 | 1 | 6 | 2.6 | 50 | 48 | 46 | 44 | 43 | 41 | 39 | 37 | 34 | 29 | 23 | 17 | 45-17 | |

| 4SSm5/12 | 4SS5/12 | 1.1 | 1.5 | 8.4 | 3.4 | 75 | 72 | 69 | 67 | 64 | 62 | 59 | 55 | 50 | 44 | 35 | 26 | 68-26 | |

| 4SSm5/17 | 4SS5/17 | 1.5 | 2 | 10.9 | 4.4 | 106 | 102 | 98 | 94 | 91 | 87 | 83 | 78 | 71 | 62 | 50 | 36 | 96-36 | |

| 4SSm5/21 | 4SS5/21 | 2.2 | 3 | 15.8 | 6.2 | 131 | 126 | 121 | 116 | 112 | 108 | 103 | 96 | 88 | 76 | 61 | 44 | 119-44 | |

| 4SSm5/32 | 4SS5/32 | 3 | 4 | 21 | 8.3 | 200 | 192 | 184 | 178 | 171 | 165 | 157 | 147 | 134 | 116 | 94 | 68 | 181-68 | |

| 4SSm5/40 | 4SS5/40 | 4 | 5.5 | 27 | 10.8 | 249 | 240 | 230 | 221 | 213 | 205 | 196 | 183 | 167 | 145 | 117 | 86 | 226-86 | |

| – | 4SS5/52 | 5.5 | 7.5 | – | 14.4 | 325 | 312 | 299 | 289 | 278 | 267 | 255 | 239 | 218 | 189 | 152 | 111 | 294-111 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||||

| Single-Phase | Three-Phase | kW | HP | Single-Phase | Three-Phase | m³/h | 0 | 0.6 | 1.2 | 2.4 | 3.6 | 4.8 | 6 | 7.2 | 8.4 | 9.6 | 10.8 | |

| 220V | 380V | 220V | 380V | l/min | 0 | 10 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | |||

| 4SSm8/5 | 4SS8/5 | 0.75 | 1 | 6 | 2.6 | H(m) | 29 | 28 | 27 | 25 | 24 | 22 | 21 | 19 | 15 | 10 | 10–27 | 9–23 |

| 4SSm8/7 | 4SS8/7 | 1.1 | 1.5 | 8.4 | 3.4 | 41 | 39 | 37 | 35 | 33 | 31 | 29 | 26 | 21 | 15 | 37-15 | 34-13 | |

| 4SSm8/10 | 4SS8/10 | 1.5 | 2 | 10.9 | 4.4 | 59 | 56 | 53 | 50 | 47 | 45 | 41 | 37 | 30 | 21 | 53-21 | 45-17 | |

| 4SSm8/12 | 4SS8/12 | 2.2 | 3 | 15.8 | 6.2 | 70 | 67 | 64 | 60 | 57 | 54 | 50 | 44 | 36 | 25 | 64-25 | 68-26 | |

| 4SSm8/18 | 4SS8/18 | 3 | 4 | 21 | 8.3 | 105 | 101 | 96 | 91 | 85 | 80 | 75 | 67 | 55 | 38 | 96-38 | 96-36 | |

| 4SSm8/24 | 4SS8/24 | 4 | 5.5 | 27 | 10.8 | 140 | 134 | 128 | 121 | 113 | 108 | 100 | 89 | 73 | 50 | 128-50 | 119-44 | |

| – | 4SS8/32 | 5.5 | 7.5 | – | 14.4 | 187 | 179 | 170 | 161 | 157 | 143 | 133 | 118 | 97 | 67 | 170-67 | 181-68 | |

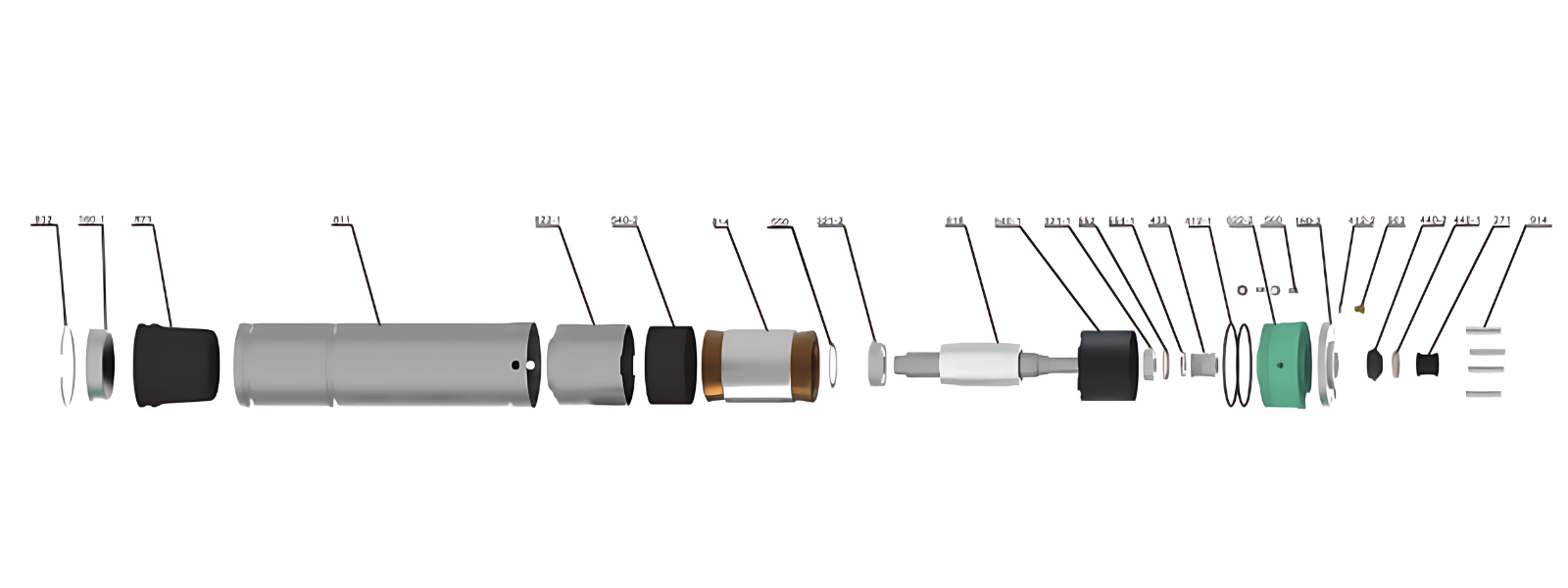

Components & Material

| No. | Part name |

|---|---|

| 160-1 | Bottom cover |

| 160-2 | Cover plate |

| 271 | Sand shaking sleeve |

| 321-1 | Deep groove ball bearing |

| 321-2 | Angular contact bearing |

| 412-1 | O-ring |

| 412-2 | O-ring |

| 433 | Mechanical seal |

| 440-1 | Anti-sand pad |

| 440-2 | Anti-sand seat |

| 540-1 | Upper spacer sleeve |

| 540-2 | Lower spacer sleeve |

| 550 | Adjusting washer |

| 552 | Wave spring |

| 554 | Flat washer |

| 560 | Locating sleeve |

| 811 | Casing |

| 814 | Stator core with winding |

| 818 | Rotor |

| 822-1 | Lower bearing block |

| 822-2 | Oil chamber |

| 823 | Pressure regulating film |

| 903 | Vent cock |

| 914 | Hexagon socket set screw |

| 932 | Retaining ring |

Application

- Agricultural Irrigation: These pumps are ideal for irrigating agricultural fields. Their ability to deliver a significant volume of water (62 gallons per minute) makes them suitable for large-scale farming operations.

- Domestic Water Supply: In rural or remote areas, these pumps can be used to extract groundwater for daily household use, ensuring a consistent and reliable water supply for cooking, cleaning, and other domestic needs.

- Industrial Use: Industries that require a steady water supply for processes or cooling can utilize these pumps. The 4SS 62GPM specification indicates a capability that can support various industrial applications.

- Livestock Rearing: Farms with livestock require a continuous water supply for drinking and sanitation purposes. These pumps can efficiently meet the water demands of livestock farming.

- Gardening and Landscaping: For large gardens and landscaping projects, these pumps can provide sufficient water for irrigation, maintaining the health and aesthetics of the greenery.

- Aquifer Management: In areas where groundwater levels need to be actively managed, such pumps can be used to extract water, helping in controlling the water table and preventing issues like waterlogging or salinity.

Application Limits

- Limited to Cooler Environments: The pump’s maximum ambient temperature limit of under 40℃ implies that it may not be suitable for extremely hot climates or environments where equipment is exposed to high temperatures. This could be a significant factor in regions with prolonged periods of high temperatures or in industrial applications where ambient temperatures are elevated.

- Restricted Sand Content: The pump’s tolerance for sand content is capped at 100g/m³. In environments where the water has higher sand content, the pump might suffer from increased wear and tear or reduced efficiency. This makes it less suitable for areas with sandy aquifers or for use in water sources prone to heavy sedimentation.

- Chemical Composition Constraints: The pump is designed to handle water with specific chemical compositions – hydrogen sulfide content up to 1.5mg/L and chloride ion content up to 400mg/L. Water sources with higher levels of these chemicals could potentially damage the pump or reduce its lifespan. Moreover, the pH range of 6.5 to 8.5 indicates that the pump might not perform well with highly acidic or alkaline water. This should be considered when the water source has a known variance in pH levels or chemical composition.

FAQ

What is the maximum depth from which this pump can extract water?

The pump can extract water from depths up to 70 meters below the static water table.

Can this pump operate in high-temperature environments?

The pump is designed for environments where the maximum ambient temperature is below 40°C. It may not perform optimally in higher temperatures.

Is this pump suitable for sandy water sources

The pump can handle water with a sand content of up to 100g/m³. It is not advisable to use it in water sources with higher sand concentrations.

What are the chemical content limitations for this pump?

The pump is designed to handle water with hydrogen sulfide content up to 1.5mg/L and chloride ion content up to 400mg/L.

What is the range of pH levels this pump can tolerate?

The pump operates efficiently in water with a pH range of 6.5 to 8.5.

Can this pump be used for both residential and agricultural applications?

Yes, it is suitable for various applications including residential, agricultural, and industrial uses, provided the environmental and water source conditions match the pump’s specifications.

What is the flow rate of this pump, and is it adjustable?

The pump has a flow rate of 62 gallons per minute (GPM). Adjustments to the flow rate would depend on the pump model and the control mechanisms in place.

What are the maintenance requirements for this type of pump?

Regular maintenance should include checking for wear and tear, ensuring the sand content in water is within limits, and monitoring the chemical composition of the water. The frequency of maintenance depends on usage and water source conditions.