6 Inch Deep Well Pump 6SE T 251GPM

Introducing the 6 Inch Deep Well Pump 6SE T 251GPM, an industrial marvel designed for robust performance in demanding environments. This high-efficiency pump delivers an impressive 251 gallons per minute, ensuring optimal water extraction from deep wells. Perfect for agricultural irrigation, community water systems, and mining operations, its durable construction promises longevity and reliability. A must-have for efficient, large-scale water management.

Features

- Stable and Efficient Operation: Features an edible oil-filled motor with a pressure-regulating membrane, delivering consistent and reliable performance.

- Easy Maintenance: Equipped with a single-phase motor that includes a start box, complete with a built-in capacitor and a current mode thermal protector for straightforward replacement and upkeep.

- High Efficiency: The pump sleeve is designed with a screw thread and incorporates single-stage floating impellers, optimizing water flow and efficiency.

- Versatile Installation: Suitable for use in boreholes 6 inches in diameter or larger, offering flexible deployment options across various settings.

- Robust Flow Rate: Engineered to handle significant flow rates, making it ideal for extensive industrial and agricultural applications.

- Energy Savings: The pump’s energy-efficient design not only ensures effective performance but also contributes to lower electricity consumption.

- Durable Construction: Built to withstand harsh environments with a corrosion-resistant build, enhancing its lifespan and reliability. ◎ User-Friendly Design: Crafted for ease of maintenance, the pump allows for quick access to internal components, simplifying any necessary service work.

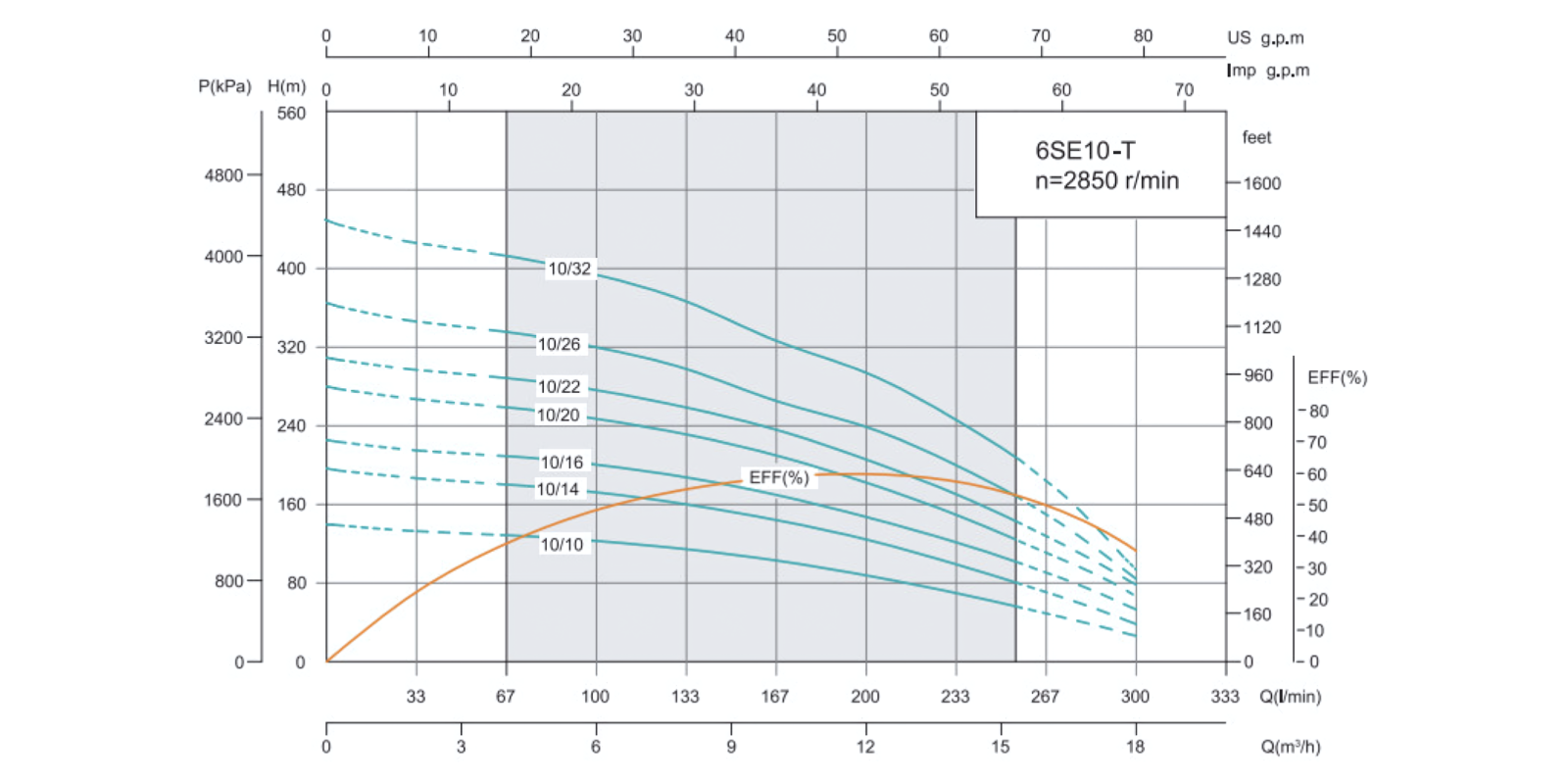

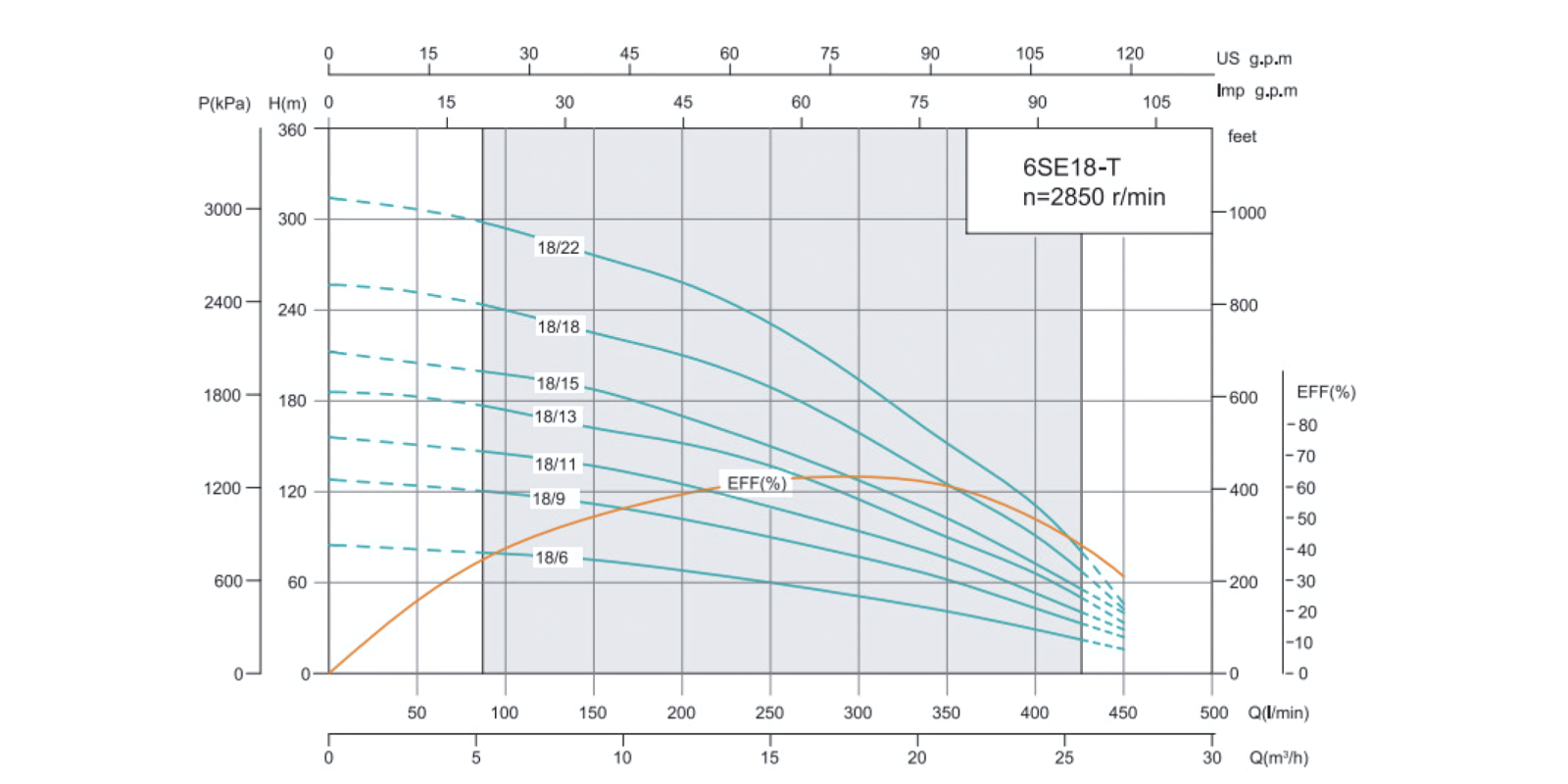

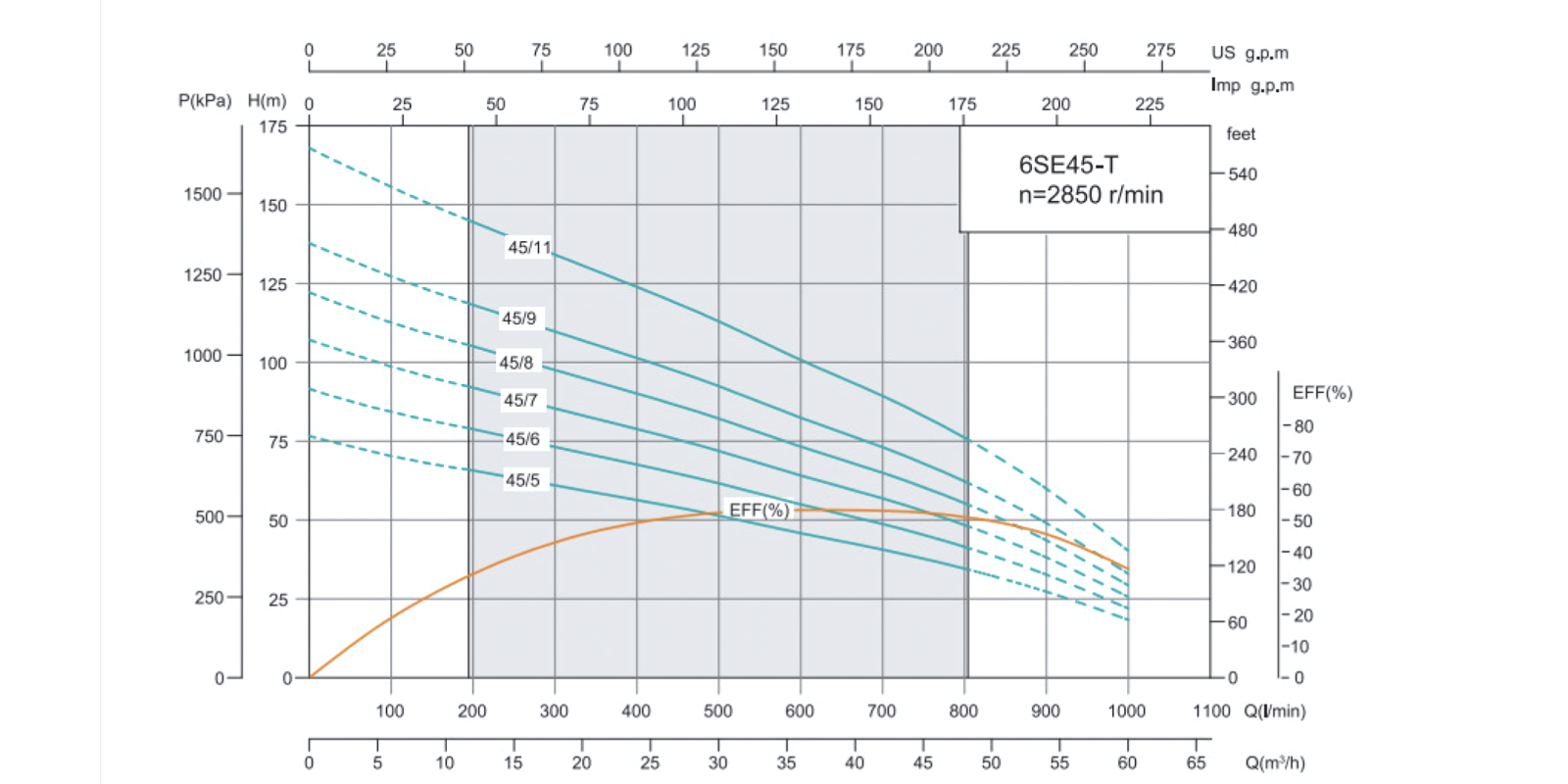

Performance Curve

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | |

| 380V | 380V | l/min | 0 | 33 | 67 | 100 | 133 | 167 | 200 | 233 | 267 | 300 | |||

| 6SE10/10T | 5.5 | 7.5 | 13 | H(m) | 140 | 133 | 129 | 123 | 115 | 102 | 87 | 69 | 48 | 25 | 129~53 |

| 6SE10/14T | 7.5 | 10 | 18 | 196 | 186 | 181 | 172 | 160 | 143 | 122 | 97 | 67 | 34 | 181~77 | |

| 6SE10/16T | 9.2 | 12.5 | 23 | 224 | 213 | 206 | 197 | 183 | 163 | 139 | 110 | 77 | 39 | 210~97 | |

| 6SE10/20T | 11 | 15 | 26 | 280 | 266 | 258 | 246 | 229 | 204 | 174 | 138 | 96 | 49 | 260~119 | |

| 6SE10/22T | 13 | 17.5 | 33 | 308 | 293 | 284 | 197 | 252 | 224 | 202 | 169 | 127 | 54 | 290~137 | |

| 6SE10/26T | 15 | 20 | 35 | 364 | 346 | 335 | 320 | 298 | 265 | 239 | 200 | 150 | 64 | 338~161 | |

| 6SE10/32T | 18.5 | 25 | 45 | 448 | 426 | 413 | 394 | 366 | 326 | 294 | 246 | 185 | 78 | 415~199 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | |

| 380V | 380V | l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | |||

| 6SE18/6T | 5.5 | 7.5 | 13 | H(m) | 85 | 82 | 79 | 75 | 68 | 60 | 51 | 41 | 29 | 16 | 80~32 |

| 6SE18/9T | 7.5 | 10 | 18 | 128 | 124 | 119 | 112 | 102 | 90 | 77 | 62 | 43 | 24 | 120~47 | |

| 6SE18/11T | 9.2 | 12.5 | 23 | 156 | 151 | 145 | 137 | 125 | 110 | 94 | 76 | 53 | 29 | 146~58 | |

| 6SE18/13T | 11 | 15 | 26 | 186 | 179 | 179 | 169 | 149 | 137 | 115 | 90 | 66 | 34 | 176~71 | |

| 6SE18/15T | 13 | 17.5 | 33 | 213 | 205 | 198 | 188 | 170 | 150 | 128 | 103 | 73 | 37 | 199~79 | |

| 6SE18/18T | 15 | 20 | 35 | 257 | 247 | 240 | 233 | 206 | 189 | 159 | 125 | 91 | 39 | 243~99 | |

| 6SE18/22T | 18.5 | 25 | 45 | 314 | 302 | 294 | 285 | 252 | 231 | 194 | 152 | 111 | 46 | 297~120 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | |

| 380V | 380V | l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 900 | 1000 | |||

| 6SE45/5T | 7.5 | 10 | 13 | H(m) | 76 | 71 | 66 | 61 | 56 | 51 | 46 | 41 | 35 | 27 | 18 | 66~ -36 |

| 6SE45/6T | 9.2 | 12.5 | 18 | 92 | 85 | 79 | 73 | 68 | 62 | 55 | 49 | 42 | 33 | 22 | 80~43 | |

| 6SE45/7T | 11 | 15 | 23 | 107 | 99 | 92 | 82 | 79 | 72 | 64 | 57 | 48 | 38 | 26 | 93~50 | |

| 6SE45/8T | 13 | 17.5 | 26 | 122 | 113 | 105 | 98 | 90 | 82 | 73 | 65 | 55 | 44 | 29 | 106~57 | |

| 6SE45/9T | 15 | 20 | 33 | 137 | 127 | 118 | 110 | 101 | 92 | 82 | 73 | 62 | 49 | 33 | 119~65 | |

| 6SE45/11T | 18.5 | 25 | 35 | 169 | 155 | 144 | 134 | 124 | 133 | 101 | 89 | 76 | 60 | 40 | 146~79 | |

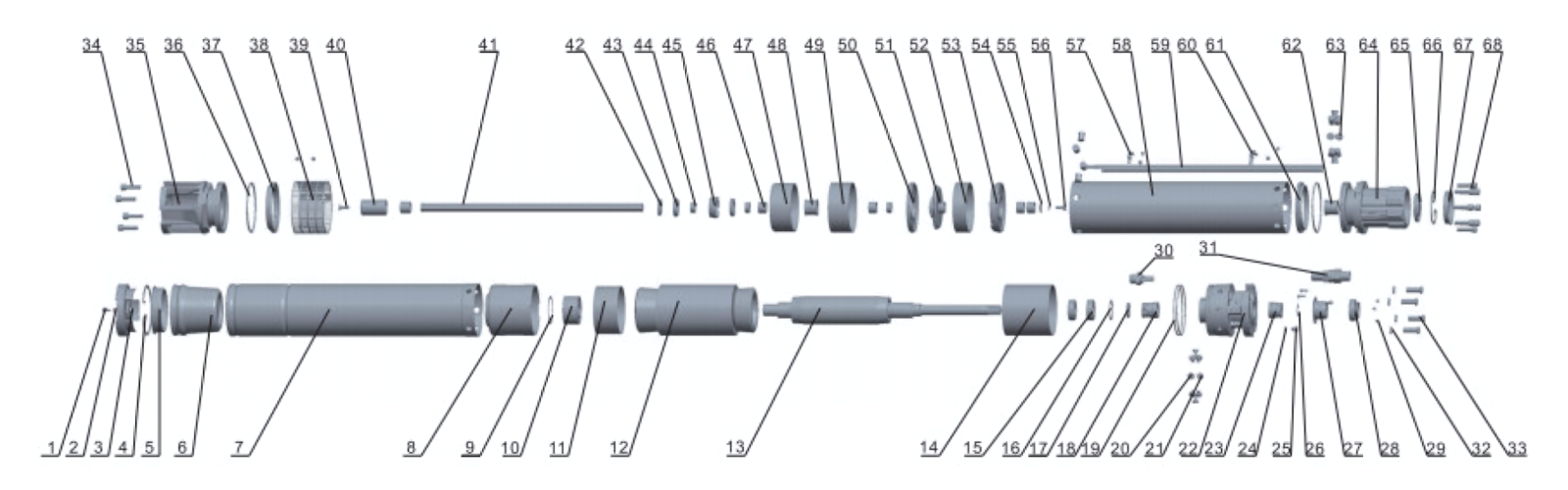

Components & Materials

| No. | Component | No. | Component | No. | Component |

| 1 | hexagon bolt | 24 | o-ring | 47 | middle bearing seat |

| 2 | spring washer | 25 | air faucet | 48 | rubber bearing |

| 3 | base | 26 | external cirdlip | 49 | lower supportingring |

| 4 | deflector | 27 | stainless steel sleeve | 50 | guide vane cover |

| 5 | bottom cover | 28 | sand defelctor | 51 | impeller |

| 6 | pressure adjusting memberane | 29 | Cross slotted flat head screw | 52 | impeller ring |

| 7 | casing | 30 | inner plug | 53 | guide vane |

| 8 | lower bearing seat | 31 | outer plug components | 54 | shaft washer |

| 9 | adjusting washer | 32 | spring washer | 55 | spring washer |

| 10 | angular contact bearing | 33 | hexagon bolt | 56 | hexagon bolt |

| 11 | lower spacer sleeve | 34 | Hexagon socket head screw | 57 | small plate |

| 12 | winding stator | 35 | inlet | 58 | pump sleeve |

| 13 | rotor | 36 | o-ring | 59 | cable plate |

| 14 | upper spacer sleeve | 37 | inlet mantle ring | 60 | small plate |

| 15 | deep groove bearing | 38 | screen fiter | 61 | discharge chamber washer |

| 16 | spring washer | 39 | cross recess pan head screw | 62 | rubber bearing |

| 17 | flat washer | 40 | coupling | 63 | positioning pin |

| 18 | mechanical seal | 41 | pump shaft | 64 | discharge chamber |

| 19 | o-ring | 42 | friction washer | 65 | valve cover |

| 20 | positioning pin | 43 | friction disk | 66 | deflector |

| 21 | countersunk screw | 44 | lower spacer | 67 | dust cover |

| 22 | oil chamber | 45 | Stationary holder | 68 | Hexagon socket head cap screws |

| 23 | mechanical seal | 46 | ceramic shaft |

Application

- Construction Work: Ideal for dewatering tasks at construction sites, ensuring efficient water management during foundation work or infrastructure development.

- Domestic Water Supply: Provides a reliable source of water for residential properties, ensuring adequate water pressure and supply for daily needs.

- Irrigation and Small Water Works: Delivers the necessary flow rate for agricultural irrigation systems and small-scale water distribution projects.

- Landscaping: Supports water features and irrigation systems in landscaping projects, enhancing aesthetic and functional aspects of garden designs.

- Water Conservancy System: Plays a critical role in managing and distributing water in conservation projects and facilities.

- Factory: Supplies process water required for various industrial operations, maintaining consistent water flow for manufacturing and processing activities.

- Municipal Water Supply: Suitable for augmenting municipal water systems, helping to distribute water across communities efficiently.

- Emergency Water Supply: Provides a dependable solution for emergency water distribution in the event of system failures or during disaster recovery operations.

- Mining Operations: Offers robust water extraction capabilities necessary for mining operations, ensuring adequate dewatering and process water supply.

Application Limits

- Maximum Ambient Temperature: The pump is designed to operate effectively in environments with ambient temperatures of up to 40℃, ensuring it performs optimally even in warm climates.

- Sand Content: It can handle water with a sand content of up to 0.01% by mass, which is critical for maintaining its functionality and preventing wear in sandy environments.

- Chemical Tolerance: Suitable for water with hydrogen sulfide content up to 1.5 mg/L and chloride ion content up to 400 mg/L. These tolerances are essential for use in areas with slightly contaminated sources.

- pH Range: The operational pH range for this pump is from 6.5 to 8.5, accommodating most natural water sources and ensuring compatibility with slightly acidic to basic water.

- Submersion Limit: It can be installed up to 70 meters below the static water table, allowing for deep well applications and ensuring adequate water pressure and supply at greater depths.

FAQ

1.What is the maximum ambient temperature for operating the 6SE T 251GPM pump?

The pump can operate in environments where the ambient temperature does not exceed 40°C (104°F).

2.Can the pump handle sandy water?

Yes, it can process water with a sand content up to 0.01% by mass, making it suitable for areas with slightly sandy water.

3.What are the chemical tolerance limits of this pump?

The pump can handle water with up to 1.5 mg/L of hydrogen sulfide and up to 400 mg/L of chloride ions.

4.What pH levels can the 6SE T 251GPM pump accommodate?

The pump is designed to work with water having a pH range from 6.5 to 8.5.

5.How deep can the pump be installed from the static water table?

It can be installed up to 70 meters (approximately 230 feet) below the static water table.

6.Is this pump suitable for residential use?

Absolutely! It’s perfect for domestic water supply needs, ensuring reliable and efficient water delivery.

7.What types of applications is the 6SE T 251GPM pump best used for?

It is ideal for a variety of applications including agricultural irrigation, domestic water supply, industrial processes, and more, thanks to its robust performance and adaptability to various water qualities and depths.