Fully Integrated Pump Variable Frequency Pump BLE

Introducing the cutting-edge, fully-integrated intelligent variable-frequency pump – a revolutionary new generation of pressurized water supply equipment. This state-of-the-art system seamlessly combines our company’s newly-developed frequency controllers, water pumps, and pressure tanks into a sleek, visually appealing package that represents the pinnacle of international advancement in the field.

What sets this pump apart is its remarkable artificial intelligence and automatic adjustment capabilities, designed to cater to the user’s every need for constant-pressure and variable-frequency water supply. By intelligently adapting to changing demands, this smart system maintains a stable pressure throughout the water supply network, ensuring that the entire setup consistently operates at peak energy efficiency.

With its unparalleled performance and eye-catching design, our fully-integrated intelligent variable-frequency pump is poised to redefine the landscape of pressurized water supply equipment. Embrace the future of water management with this groundbreaking innovation, and experience the benefits of a system that effortlessly optimizes itself to deliver reliable, efficient, and eco-friendly performance.

Application:

Residential Water Supply: Ideal for pressurizing water in high-rise buildings, apartments, and villas, ensuring a consistent water supply to all floors.

Public Facilities: Perfect for maintaining water pressure in schools, restaurants, stations, hospitals, and stadiums, providing reliable water access for large numbers of people.

Commercial Properties: Excellent choice for hotels, office buildings, and department stores, guaranteeing a steady water supply for various commercial needs.

Agricultural Irrigation: Suitable for farms, orchards, and parks, delivering constant water pressure for efficient irrigation systems.

Industrial Applications: Optimal for manufacturing plants, food processing facilities, and other industrial settings requiring constant-pressure water supply, ensuring smooth operations and production.

Function:

- The fluctuation range of the operating pressure of variable-frequency pump shall be no more than 0.01MPa.

- The pump will stop working in case of idling without water.

- It is able to inspect several faults concerning disconnection, overcurrent, overload, and grounding.

Features:

Frequency Converter:

– IP65 rated, ensuring a safe and reliable operation

– Highly integrated with the water pump, resulting in a compact size for easy installation and space-saving

Automatic Control:

– Fully automatic control system that adjusts the operating state based on the user’s network pressure

– Achieves optimal working conditions and energy-saving performance

– Automatic pressure maintenance and sleep mode when no water is being used, significantly improving energy efficiency

– Real-time tracking, judgment, and treatment of water pump failures

User-Friendly Operation:

– Direct man-machine interaction through keys and display on the frequency converter

– Users can easily set pressure parameters based on their actual operating conditions and access relevant information

– Abnormality information is readily available to the user

Constant-Power Operation:

– Controller adjusts based on actual operation when reaching power limits

– Maintains a consistent output power while protecting the motor

– Ensures maximum water consumption for the user

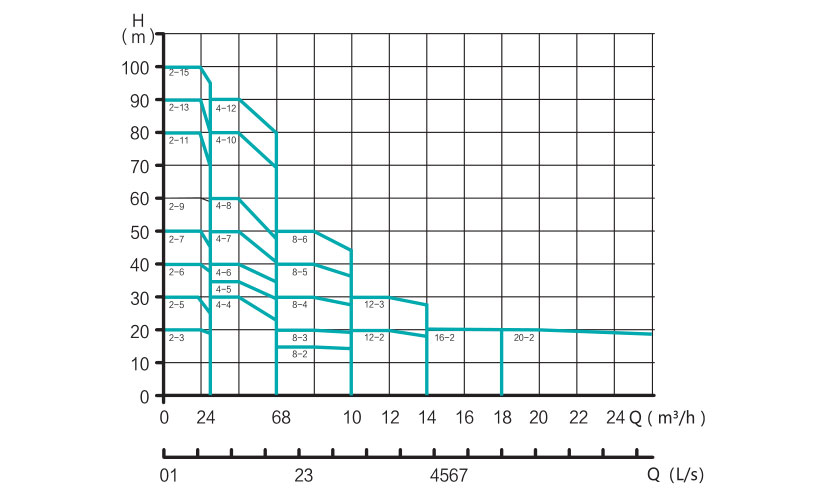

Equipment spectrum:

Action description:

The automatic identification module utilizes a pressure sensor to monitor the system’s pressure and compare it with the preset value. It then sends a continuous analog signal to the frequency converter, which adjusts the motor’s operating frequency based on the signal’s fluctuations. This process ensures a constant-pressure water supply that adapts to the user’s needs.

When water consumption is high, the system automatically increases the rotational speed and power to maintain the desired pressure. Conversely, when no water is being used, the system enters a sleep mode once the set pressure is achieved, maximizing energy efficiency.

If water usage is low or the pressure drops to 80% due to pipe leakage, the frequency controller signals the motor to operate and restore pressure to the preset level. This intelligent design guarantees a reliable, energy-saving water supply that caters to the user’s requirements.

Performance parameters:

| No | Model | Input voltage | Constant pressure value set (Bar) | The factory set constant value (rated pressure) Bar | Inlet diameter | Outlet diameter | Single pump power | The highest lift (zero flow) m | Rated flow m³/h | Pressure tank volume L |

| A01 | BWE2-6 | 220V/380V | 0.5-4 | 4 | G1 | G1 | 0.75 | 56 | 2 | 3 |

| A02 | 8WE4-4 | 220V/380V | 0.5-3 | 3 | G1¼ | G1 | 0.75 | 38 | 4 | 3 |

| A03 | BWE8-2 | 220V/380V | 0.5-1.5 | 1.5 | G2 | G2 | 0.75 | 22 | 8 | 5 |

| A04 | BWE8-3 | 220V/380V | 0.5-2 | 2 | G2 | G2 | 1.1 | 32 | 8 | 5 |

| A05 | BWE8-4 | 220V/380V | 0.5-3 | 3 | G2 | G2 ! | 1.5 | 43 | 8 | 5 |

| A06 | BWE8-5 | 220V/380V | 0.5-4 | 4 | G2 | G2 | 2.2 | 54 | 8 | 5 |

| A07 | BWE12-2 | 220V/380V | 0,5-2 | 2 | G2 | G2 | 1.2 | 23 | 12 | 5 |

| A08 | BWE12-3 | 220V/380V | 0.5-3 | 3 | G2 | G2 | 1.8 | 35 | 12 | 5 |

| A09 | BWE16-2 | 220V/380V | 0.5-2 | 2 | G2 | G2 | 2.2 | 27 | 16 | 5 |

| A10 | BWE20-1 | 220V/380V | 0.5-1 | 1 | G2 | G2 | 1.1 | 13 | 20 | 5 |

| A11 | BWE20-2 | 220V/380V | 0.5-2 | 2 | G2 | G2 | 2.2 | 26.5 | 20 | 5 |

| A12 | BWJE2-6 | 220V/380V | 0.5-4 | 4 | G1 | G1 | 0.75 | 56 | 2 | 3 |

| A13 | BWJE4-4 | 220V/380V | 0.5-3 | 3 | G1¼ | G1 | 0.75 | 38 | 4 | 3 |

| A14 | BWJE4-5 | 220V/380V | 0.5-3.5 | 3.5 | G1½ | G1 | 1.1 | 47 | 4 | 3 |

| A15 | BWJE4-6 | 220V/380V | 0.5-4.5 | 4.5 | G1½ | G1 | 1.1 | 57 | 4 | 3 |

| A16 | BWJE8-2 | 220V/380V | 0.5-1.5 | 1.5 | G1½ | G1V | 0.75 | 22 | 8 | 5 |

| A17 | BWJE8-3 | 220V/380V | 0.5-2 | 2 | G1½ | G1¼ | 1.1 | 32 | 8 | 5 |

| A18 | BWJE8-4 | 220V/380V | 0.5-3 | 3 | G1½ | G1¼ | 1.5 | 43 | 8 | 5 |

| A19 | BWJE8-5 | 220V/380V | 0.5-4 | 4 | G1½ | G1¼ | 2.2 | 54 | 8 | 5 |

| A20 | BWJE12-2 | 220V/380V | 0.5-2 | 2 | G1½ | G1¼ | 1.2 | 23 | 12 | 5 |

| A21 | BWJE12-3 | 220V/380V | 0.5-3 | 3 | G1½ | G1¼ | 1.8 | 35 | 12 | 5 |

| A22 | BWJE16-2 | 220V/380V | 0.5-2 | 2 | G1½ | G1¼ | 2.2 | 27 | 16 | 5 |

| A23 | BWJE20-1 | 220V/380V | 0.5-1 | 1 | G2 | G2 | 1.1 | 13 | 20 | 5 |

| A24 | BWJE20-2 | 220V/380V | 0.5-2 | 2 | G2 | G2 | 2.2 | 26.5 | 20 5 | 5 |

| B01 | BL(T)E2-6 | 220V/380V | 0.5-4 | 4 | DN25 | DN25 | 0.75 | 58 | 2 3 | 3 |

| B02 | BL(T)E2-7 | 220V/380V | 0.5-5 | 5 | DN25 | DN25 | 0.75 | 68 | 2 | 3 |

| B03 | BL(T)E2-9 | 220V/380V | 0.5-6 | 6 | DN25 | DN25 | 1.1 | 87 | 2 5 | 5 |

| B04 | BL(T)E2-11 | 220V/380V | 0.5-8 | 8 | DN25 | DN25 | 1.1 | 106 | 2 5 | 5 |

| B05 | BL(T)E2-13 | 220V/380V | 0.5-9 | 9 | DN25 | DN25 | 1.5 | 124 | 2 | 5 |

| B06 | BL(T)E2-15 | 220V/380V | 0.5-10 | 10 | DN25 | DN25 | 1.5 | 138 | 2 5 | 5 |

| B07 | BL(T)E4-4 | 220V/380V | 0.5-3 | 3 | DN32 | DN32 | 0.75 | 38 | 4 3 | 3 |

| B08 | BL(T)E4-5 | 220V/380V | 0.5-3.5 | 3.5 | DN32 | DN32 | 1.1 | 47 | 4 | 3 |

| B09 | BL(T)E4-6 | 220V/ 380V | 0.5-4 | 4 | DN32 | DN32 | 1.1 | 58 | 4 3 | 3 |

| B10 | BL(T)E4-7 | 220V/380V | 0.5-5 | 5 | DN32 | DN32 | 1.5 | 69 | 4 3 | 3 |

| B11 | BL(T)E4-8 | 220V/380V | 0.5-6 | 6 | DN32 | DN32 | 1.5 | 78 | 4 | 5 |

| B12 | BL(T)E4-10 | 220V/380V | 0.5-8 | 8 | DN32 | DN32 | 2.2 | 96 | 4 | 5 |

| B13 | BL(T)E4-12 | 220V/380V | 0.5-9 | 9 | DN32 | DN32 | 2.2 | 117 | 4 | 5 |

| B14 | BL(T)E8-2 | 220V/380V | 0.5-1.5 | 1.5 | DN40 | DN40 | 0.75 | 22 | 8 | 5 |

| B15 | BL(T)E8-3 | 220V/380V | 0.5-2 | 2 | DN40 | DN40 | 1.1 | 32 | 8 | 5 |

| B16 | BL(T)E8-4 | 220V/380V | 0.5-3 | 3 | DN40 | DN40 | 1.5 | 42 | 8 | 5 |

| B17 | BL(T)E8-5 | 220V/380V | 0.5-4 | 4 | DN40 | DN40 | 2.2 | 53 | 8 | 5 |

| B18 | BL(T)E8-6 | 220V/380V | 0.5-5 | 5 | DN40 | DN40 | 2.2 | 62 | 8 | 5 |

| B19 | BL(T)E12-2 | 220V/380V | 0.5-2 | 2 | DN50 | DN50 | 1.5 | 26 | 12 | 5 |

| B20 | BL(T)E12-3 | 220V/380V | 0.5-3 | 3 | DN50 | DN50 | 2.2 | 38 | 12 | 5 |

| B21 | BL(T)E16-2 | 220V/380V | 0.5-2 | 2 | DN50 | DN50 | 2.2 | 28 | 16 | 5 |

| B22 | BL(T)E20-2 | 220V/380V | 0.5-2 | 2 | DN50 | DN50 | 2.2 | 30 | 20 | 5 |

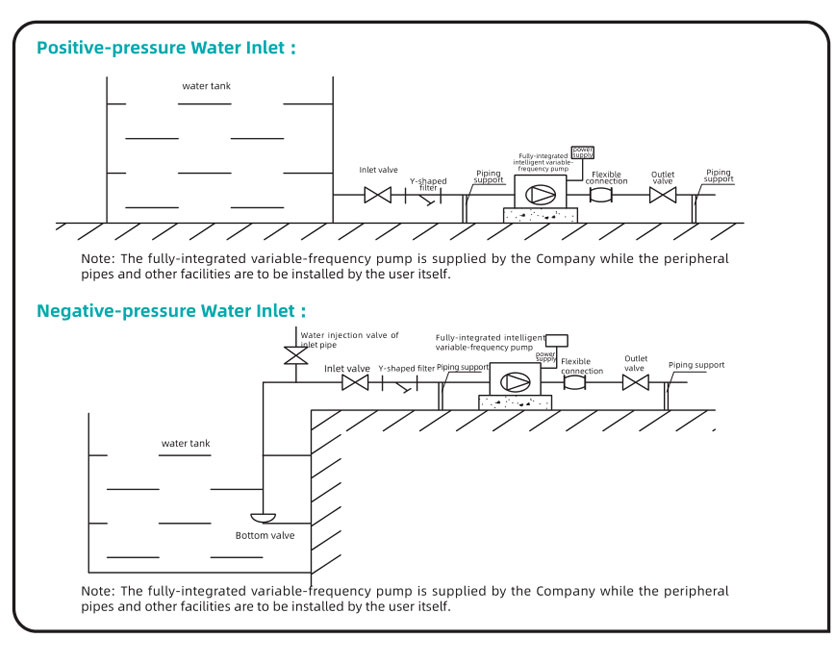

Installation Diagram:

Installation precautions:

Here’s a concise summary of the installation instructions for the variable-frequency pump in English:

1. Indoor installation: Ensure a clean, dry, and interference-free environment. Outdoor installation: Provide proper shelter for the pump.

2. Ensure a firm, stable, and level assembling floor.

3. Prefer positive pressure installation at the inlet; avoid negative-pressure suction when possible. If negative-pressure installation is necessary, use a high-quality bottom valve and perform regular maintenance.

4. Inlet and outlet pipe diameters should be larger than the pump’s diameter.

5. Verify that the power supply meets the pump’s requirements.

6. Install inlet and outlet valves and flexible connections for easy maintenance and noise reduction.

7. For positive pressure inlet installation: Open the vent valve and release air before use, closing it only when water flows out. For negative pressure inlet installation: Fill the suction pipe and pump chamber with water before starting the pump, using a filling valve on the suction pipe.

Reference for Model Selection:

| No | Accessories for water supply | Rated flow (L/s) | Equivalent | Nominal diameter of connecting pipe (mm) | Minimum operating pressure (MPa) |

| 1 | Washtub, mop basin, washbasin Single-valve faucet Single-valve faucet Mixed-water faucet | 0.15~ 0.20,0.30~ 0.40,0.15~ 0.20(0.14) | 0.75~ 1,00 1.5一2.00 0.75 ~ 1,00(0.70) | 15 20 15 | 0. 050 |

| 2 | Washbasin Single-valve faucet Mixed-water faucet | 0.15 0.15 (0.10) | 0.75 0.75(0.50) | 15 15 | 0. 050 |

| 3 | Washbasin | 0.10 0.15(0.10) | 0.50 0.75(0.5) | 15 15 | 0. 050 |

| Sensor faucet Mixed-water faucet | |||||

| Bathtub | |||||

| 4 | Single-valve faucet Mixed-water faucet (including converter with shower) | 0.20 0.24(0.20) | 1.00 1.2(1.0) | 15 15 | 0. 050 0.050一0.0 70 |

| 5 | Shower Mixing valve | 0.15(0.10) | 0.75(0.50) | 15 | 0.050 0.100 |

| 6 | Closet pan Float valve of flushing cistern Delay-driven self-closing flush valve | 0.10 1.20 | 0.50 6.00 | 15 25 | 0.020 0.10~ 0.15 |

| 7 | Urinal Manual or automatic self-closing flush valve Inlet valve of automatic flushing cistern | 0.10 0.10 | 0.50 0.50 | 15 15 | 0.050 0. 020 |

| 8 | Perforated fushing pipe of urinal (in m) | 0.05 | 0.25 | 15一20 | 0.015 |

| 9 | Faucet of bidet | 0.10(0.07) | 0.50(0.35) | 15 | 0. 050 |

| 10 | Pan closet used in a hospital | 0.10(0.07) | 1.00 | 15 | 0.050 |

| 11 | Gooseneck -type faucet for testing in a laboratory | 0.07 | 0.35 | 15 | 0.020 |

| Single- linkage Doube-linkage Triple-linkage | 0.15 0.20 | 0.75 1.00 | 15 15 | 0.020 0.020 | |

| 12 | Nozzle of drinking fountain | 0.05 | 0.25 | 15 | 0.050 |

| 13 | Sprinkler | 0.40 0.70 | 2.00 3.50 | 20 25 | 0.050 ~ 0.100 0.050一0.100 |

| 14 | Flushing faucet for indoor ground | 0.20 | 1.00 | 15 15 | 0.050 |

| 15 | Faucet of domestic washing machine | 0.20 | 1.00 | 15 15 | 0.050 |

Calculation of minimum pressure:

Here’s a summary of the minimum pressure requirements for the water supply equipment:

The minimum pressure for the water supply equipment (in MPa) is approximately equal to:

1/100 * (Ha + Hf) + Pe

Where:

– Ha is the actual lift from the suction surface to the highest fixture, measured in meters (m).

– Hf is the loss due to piping and bending, which should be calculated as 6m to 10m.

– Pe is the minimum necessary pressure for the highest sanitary fixture, which can be found in Table I.

In other words, the minimum pressure should be calculated by considering the pressure at the suction surface of the water pump, plus the minimum necessary pressure for the highest sanitary fixture being used.

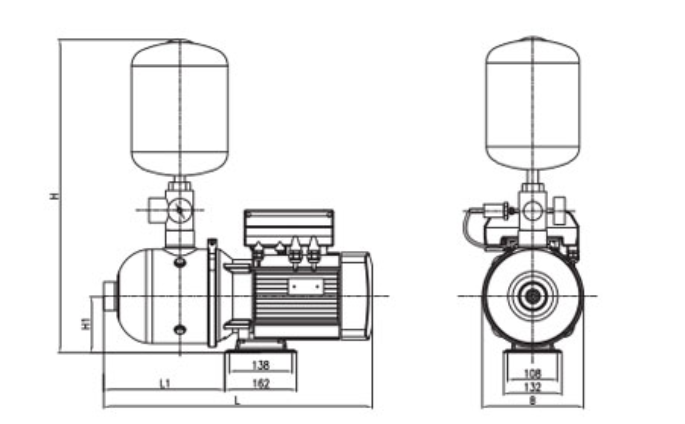

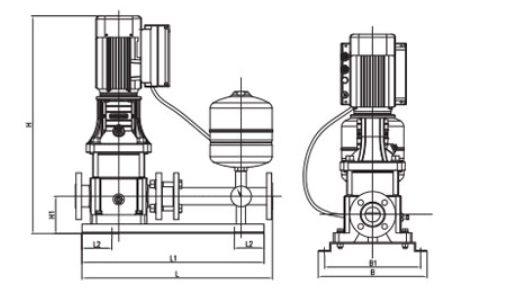

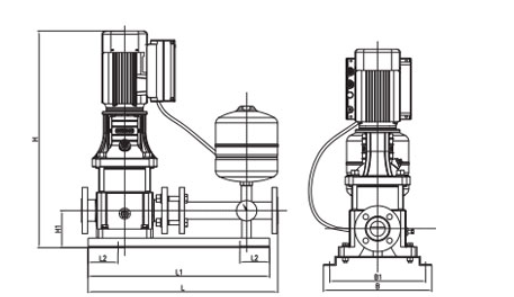

Overall Dimensions of Variable-frequency Pump:

| Model | L | L1 | B | H1 | H | N.W | G.W |

| (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | (kg) | |

| BWE2-6 | 424 | 159 | 166 | 111 | 530 | 19 | 21.5 |

| BWE4-4 | 424 | 159 | 166 | 111 | 530 | 19 | 21.5 |

| BWE8-2 | 536 | 270 | 228 | 118 | 626 | 19 | 22.3 |

| BWE8-3 | 536 | 270 | 228 | 118 | 626 | 25 | 28.3 |

| BWE8-4 | 574 | 270 | 228 | 118 | 626 | 29 | 32.3 |

| BWE8-5 | 574 | 270 | 228 | 118 | 626 | 33 | 36.3 |

| BWE12-2 | 536 | 270 | 228 | 118 | 626 | 25 | 28.3 |

| BWE12-3 | 574 | 270 | 228 | 118 | 626 | 29 | 32.3 |

| BWE16-2 | 574 | 270 | 228 | 118 | 626 | 32 | 35.3 |

| BWE20-1 | 536 | 270 | 228 | 118 | 626 | 25 | 28.3 |

| BWE20-2 | 574 | 270 | 228 | 118 | 626 | 33 3 | 36.3 |

| Model | L | L1 | B | H1 | H | N.W | G.W |

| (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | (kg) | |

| BWJE2-6 | 440 | 158 | 158 | 110 | 498 | 20 | 22.8 |

| BWJE4-4 | 441 | 159 | 158 | 110 | 498 | 19 | 21.5 |

| BWJE4-5 | 469 | 187 | 158 | 111 | 498 | 22 | 25 |

| BWJE4-6 | 496 | 214 | 158 | 111 | 498 | 23 | 25.5 |

| BWJE8-2 | 405 | 120 | 158 | 118 | 568 | 23 | 26.7 |

| BWJE8-3 | 437 | 152 | 158 | 118 | 568 | 25 | 28.8 |

| BWJE8-4 | 492 | 183 | 168 | 118 | 568 | 30 | 33.3 |

| BWJE8-5 | 524 | 215 | 168 | 118 | 568 | 32 | 35.9 |

| BWjE12-2 | 405 | 120 | 158 | 118 | 568 | 26 | 29.3 |

| BWJE12-3 | 460 | 151 | 168 | 118 | 568 | 31 | 34.3 |

| BWjE16-2 | 441 | 132 | 168 | 118 | 568 | 34 | 37.9 |

| BWJE20-1 | 391 | 106 | 158 | 118 | 583 | 26 | 29.3 |

| BWJE20-2 | 459 | 150 | 168 | 118 | 583 | 31 | 34.3 |

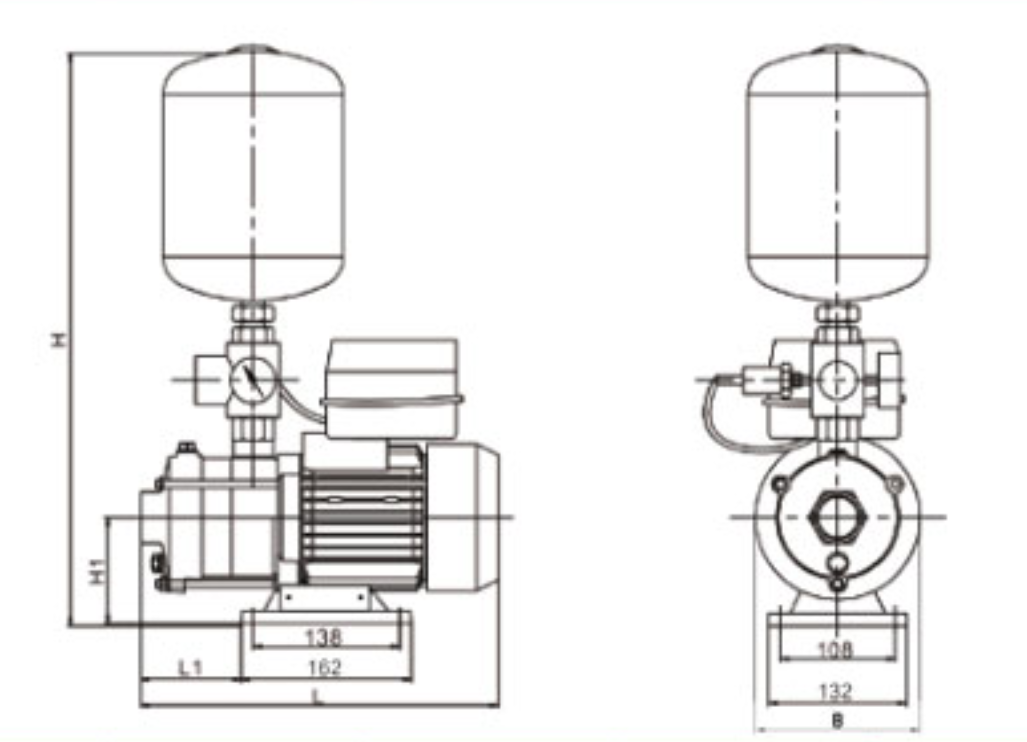

Overall Dimensions of Variable-frequency Pump:

| Model | L | L1 | L2 | B | B1 | H | H1 | N.W.(kg) | G.W.(kg) | ||

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | BLE | BLTE | BLE | BLTE | |

| BL(T)E2-6 | 600 | 550 | 100 | 320 | 280 | 625 | 80 | 37 | 43 | 52 | 58 |

| BL(T)E2-7 | 600 | 550 | 100 | 320 | 280 | 643 | 80 | 37 | 43 | 52 | 58 |

| BL(T)E2-9 | 600 | 550 | 100 | 320 | 280 | 679 | 80 | 40 | 46 | 57 | 63 |

| BL(T)E2-11 | 600 | 550 | 100 | 320 | 280 | 715 | 80 | 41 | 47 | 58 | 64 |

| BL(T)E2-13 | 600 | 550 | 100 | 320 | 280 | 809 | 80 | 44 | 51 | 63 | 70 |

| BL(T)E2-15 | 600 | 550 | 100 | 320 | 280 | 845 | 80 | 45 | 51 | 64 | 70 |

| BL(T)E4-4 | 600 | 550 | 100 | 320 | 280 | 625 | 80 | 37 | 44 | 52 | 59 |

| BL(T)E4-5 | 600 | 550 | 100 | 320 | 280 | 652 | 80 | 39 | 46 | 54 | 61 |

| BL(T)E4-6 | 600 | 550 | 100 | 320 | 280 | 679 | 80 | 40 | 47 | 57 | 64 |

| BL(T)E4-7 | 600 | 550 | 100 | 320 | 280 | 764 | 80 | 43 | 51 | 61 | 69 |

| BL(T)E4-8 | 600 | 550 | 100 | 320 | 280 | 791 | 80 | 44 | 51 | 62 | 69 |

| BL(T)E4-10 | 600 | 550 | 100 | 320 | 280 | 845 | 80 | 48 | 55 | 66 | 73 |

| BL(T)E4-12 | 600 | 550 | 100 | 320 | 280 | 899 | 80 | 49 | 57 | 69 | 77 |

| Model | L | L1 | L2 | B | B1 | H | H1 | N.W.(kg) | G.W.(kg) | ||

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | BLE | BLTE | BLE | BLTE | |

| BL(T)E8-2 | 750 | 700 | 100 | 360 | 320 | 650 | 120 | 53 | 63 | 72 | 82 |

| BL(T)E8-3 | 750 | 700 | 100 | 360 | 320 | 680 | 120 | 55 | 65 | 74 | 84 |

| BL(T)E8-4 | 750 | 700 | 100 | 360 | 320 | 760 | 120 | 59 | 69 | 80 | 90 |

| BL(T)E8-5 | 750 | 700 | 100 | 360 | 320 | 790 | 120 | 63 | 73 | 84 | 94 |

| BL(T)E8-6 | 750 | 700 | 100 | 360 | 320 | 820 | 120 | 64 | 74 | 85 | 95 |

| BL(T)E12-2 | 750 | 700 | 100 | 360 | 320 | 713 | 120 | 59 | 69 | 80 | 90 |

| BL(T)E12-3 | 750 | 700 | 100 | 360 | 320 | 745 | 120 | 62 | 72 | 83 | 93 |

| BL(T)E16-2 | 750 | 700 | 100 | 360 | 320 | 740 | 120 | 62 | 73 | 83 | 94 |

| BL(T)E20-2 | 750 | 700 | 100 | 360 | 320 | 740 | 120 | 64 | 74 | 85 | 95 |

FAQ:

- Q: What makes this fully-integrated intelligent variable-frequency pump revolutionary compared to other pressurized water supply equipment?

A: This cutting-edge pump seamlessly combines our company’s newly-developed frequency controllers, water pumps, and pressure tanks into a single, visually appealing package. It represents the pinnacle of international advancement in the field, offering unparalleled artificial intelligence and automatic adjustment capabilities. - Q: How does the pump’s artificial intelligence benefit users?

A: The pump’s artificial intelligence is designed to cater to the user’s every need for constant-pressure and variable-frequency water supply. By intelligently adapting to changing demands, the system maintains stable pressure throughout the water supply network, ensuring that the entire setup consistently operates at peak energy efficiency. - Q: What are the key features that set this pump apart from others in the market?

A: The fully-integrated intelligent variable-frequency pump boasts a sleek and eye-catching design, combined with its remarkable performance. Its ability to automatically adjust to changing demands and maintain stable pressure throughout the water supply network sets it apart from other pressurized water supply equipment. - Q: How does this pump contribute to eco-friendliness and energy efficiency?

A: By intelligently adapting to changing demands and maintaining stable pressure, the pump ensures that the entire water supply system consistently operates at peak energy efficiency. This optimization leads to reduced energy consumption and a more eco-friendly operation. - Q: What can users expect when they switch to this groundbreaking innovation in water management?

A: Users who embrace this fully-integrated intelligent variable-frequency pump can expect a revolutionary experience in pressurized water supply. They will benefit from a system that effortlessly optimizes itself to deliver reliable, efficient, and eco-friendly performance, redefining the landscape of water management.