6 Inch Deep Well Pumps 6SS 343 GPM

6SS Deep Well Pump – Ensuring Operation and Durability of Use for Effective and Efficient Water Draw-off to Large Depth. The said pump is to be operated under a formidable flow rate capacity of 343 gallons per minute, fabricated within a 6-inch stainless steel housing that assures durability and resistance from corrosion. Such usage would primarily be best fitted for agricultural irrigation and municipal water supplies, along with an array of industrial applications. The 6SS is now available with advanced hydraulic technology for remarkable performance. Equipped with a high-capacity design, it holds large water volumes, thus being ideal for users whose first concern is nothing short of reliability and performance in water pumping.

Features:

- Stable and Reliable Operation: Features an edible oil-filled motor and a pressure-regulating membrane for enhanced performance under varying pressures.

- Convenient Maintenance: Equipped with a single-phase motor, this pump includes a start box with a built-in capacitor and a current mode thermal protector, facilitating easy replacements.

- Precision Engineering: The pump sleeve, designed with a precise screw thread and equipped with single-stage floating impellers, maximizes efficiency and minimizes wear.

- Flexible Installation: Compatible with boreholes 6 inches in diameter or larger, offering flexibility across various well sizes.

- Optimized for Deep Wells: Engineered to meet the challenges of extensive water extraction, making it ideal for demanding applications.

- Quiet Operation: Its robust construction significantly reduces vibration and noise, making it suitable for residential environments.

- Sand Protection: Features an anti-sand mechanism that prevents the ingress of sand and other particulates, thus prolonging the pump’s lifespan and reducing maintenance requirements.

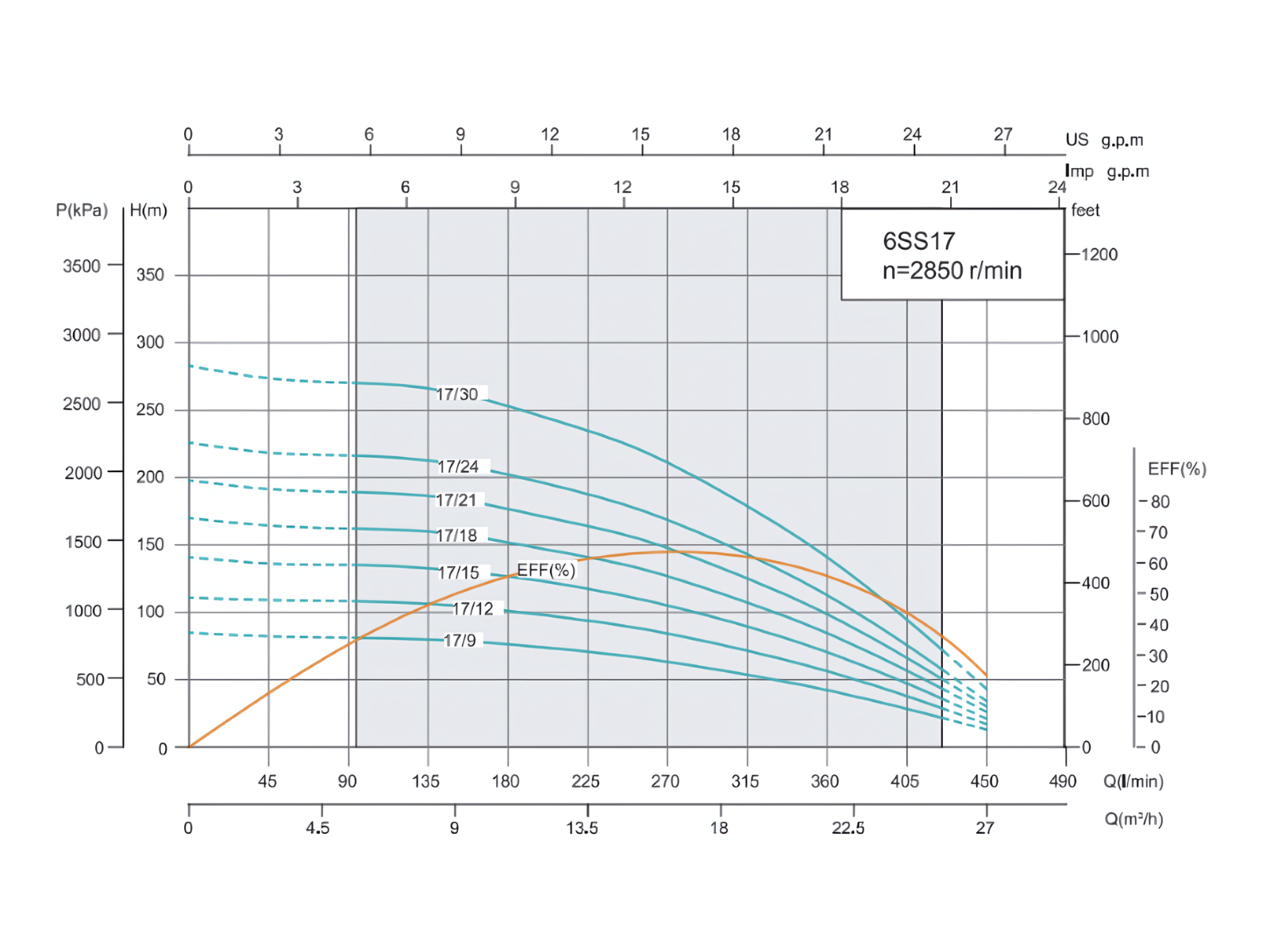

Performance Curve

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | |

| 380V | 380V | l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 325 | 400 | 450 | |||

| 6SS17/9 | 5.5 | 7.5 | 13 | H(m) | 85 | 82 | 81 | 79 | 74 | 67 | 57 | 45 | 30 | 13 | 81-38 |

| 6SS17/12 | 7.5 | 10 | 18 | 111 | 109 | 108 | 105 | 98 | 89 | 76 | 60 | 40 | 17 | 108-50 | |

| 6SS17/15 | 9.2 | 12.5 | 23 | 141 | 136 | 135 | 131 | 123 | 111 | 95 | 75 | 50 | 21 | 135-63 | |

| 6SS1 7/18 | 11 | 15 | 26 | 170 | 164 | 162 | 158 | 147 | 134 | 114 | 90 | 60 | 26 | 162-76 | |

| 6SS17/21 | 13 | 17.3 | 33 | 198 | 191 | 189 | 184 | 171 | 156 | 133 | 105 | 70 | 30 | 189-88 | |

| 6SS17124 | 15 | 20 | 35 | 226 | 218 | 216 | 210 | 196 | 178 | 152 | 120 | 80 | 34 | 216-101 | |

| 6SS17/30 | 18.5 | 25 | 45 | 283 | 273 | 270 | 263 | 245 | 223 | 190 | 150 | 100 | 43 | 270-126 | |

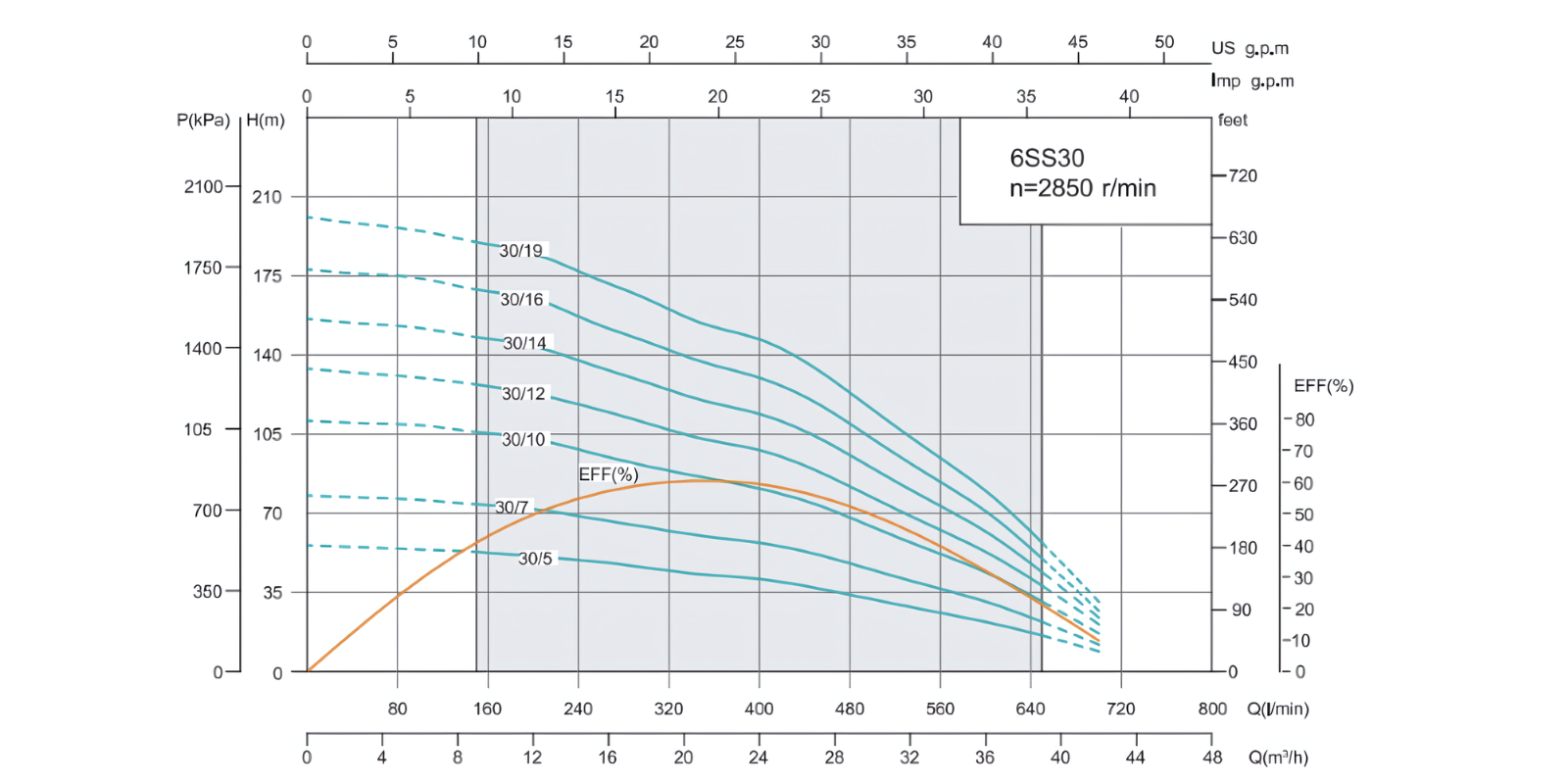

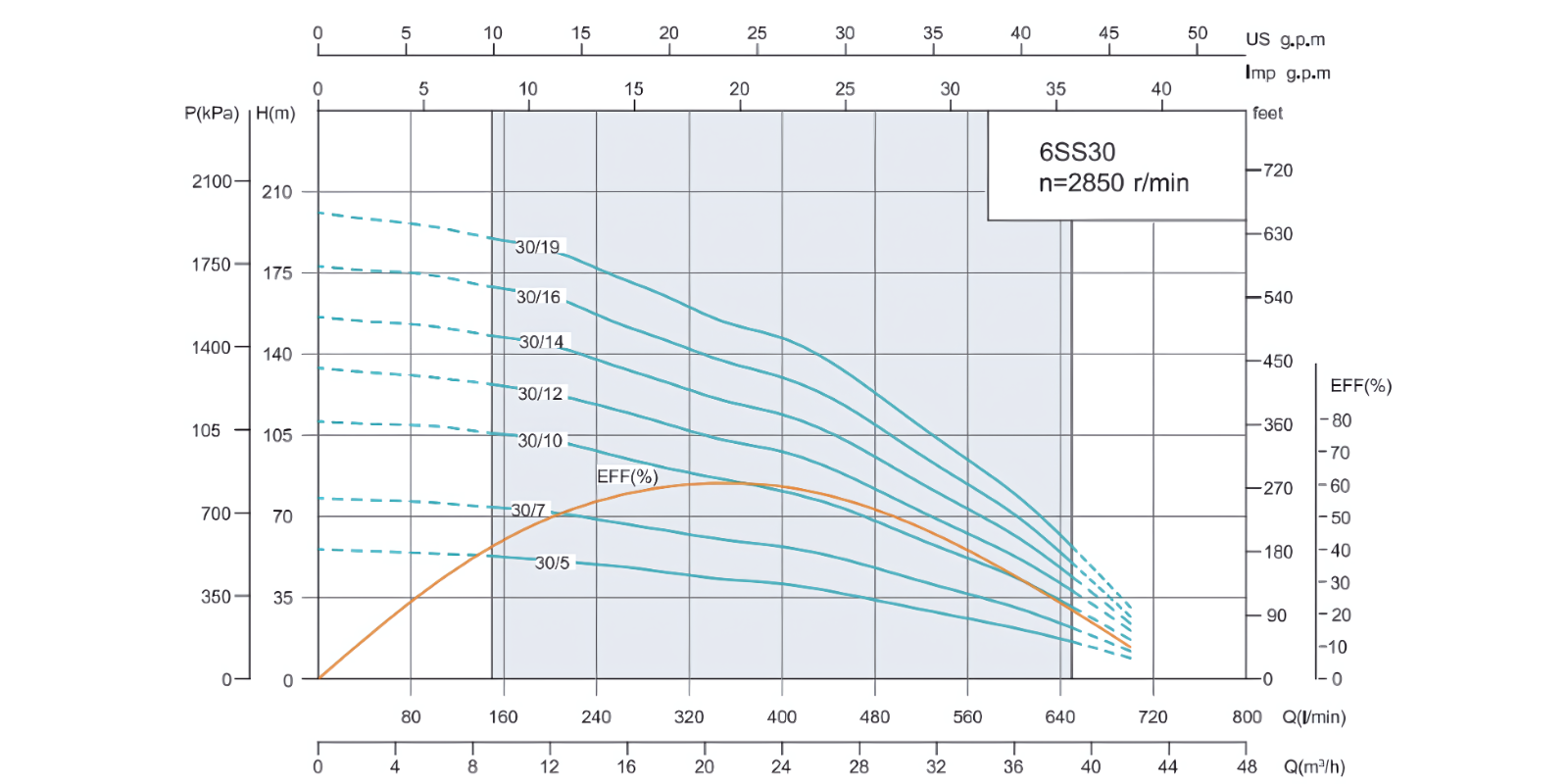

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| 380V | 380V | l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 325 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | |||

| 6SS30/5 | 5.5 | 7.5 | 13 | H(m) | 56 | 55 | 54 | 53 | 51 | 49 | 46 | 43 | 41 | 37 | 32 | 27 | 22 | 16 | 9 | 53-16 |

| 6SS30/7 | 7.5 | 10 | 18 | 78 | 77 | 76 | 74 | 72 | 68 | 64 | 60 | 57 | 45 | 38 | 38 | 31 | 22 | 12 | 74-22 | |

| 6SS30/10 | 9.2 | 12.5 | 23 | 111 | 110 | 109 | 106 | 103 | 97 | 91 | 86 | 81 | 64 | 54 | 54 | 44 | 31 | 17 | 106-31 | |

| 6SS30/2 | 11 | 15 | 26 | 134 | 132 | 130 | 127 | 123 | 117 | 110 | 103 | 98 | 77 | 65 | 65 | 53 | 38 | 21 | 127~38 | |

| 6SS30/14 | 13 | 17.5 | 33 | 156 | 154 | 152 | 148 | 144 | 136 | 128 | 120 | 114 | 90 | 76 | 76 | 62 | 44 | 24 | 148-44 | |

| 6SS30/16 | 15 | 20 | 35 | 178 | 176 | 174 | 169 | 165 | 155 | 146 | 137 | 130 | 103 | 87 | 87 | 71 | 50 | 27 | 169-50 | |

| 6SS30/19 | 18.5 | 25 | 45 | 201 | 198 | 195 | 190 | 185 | 175 | 165 | 154 | 147 | 116 | 98 | 98 | 80 | 57 | 31 | 190-57 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 6 | 12 | 18 | 24 | 30 | 42 | 48 | 54 | 60 | 66 | 72 | 78 | |

| 380V | 380V | l/min | 0 | 100 | 200 | 300 | 400 | 500 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | |||

| 6SS60/3 | 5.5 | 7.5 | 13 | H(m) | 40 | 40 | 39 | 37 | 37 | 34 | 32 | 28 | 26 | 22 | 17 | 12 | 7 | 37~7 |

| 6SS60/4 | 7.5 | 10 | 18 | 54 | 53 | 52 | 51 | 49 | 46 | 40 | 38 | 34 | 30 | 23 | 16 | 9 | 51~9 | |

| 6SS60/5 | 9.2 | 12.5 | 23 | 67 | 66 | 65 | 64 | 61 | 57 | 50 | 47 | 43 | 37 | 29 | 20 | 11 | 64~11 | |

| 6SS60/6 | 11 | 15 | 26 | 80 | 79 | 78 | 77 | 73 | 68 | 60 | 56 | 52 | 44 | 35 | 24 | 13 | 77~13 | |

| 6SS60/7 | 13 | 17.3 | 33 | 94 | 93 | 91 | 89 | 85 | 80 | 70 | 65 | 60 | 52 | 41 | 27 | 15 | 89~15 | |

| 6SS60/8 | 15 | 20 | 35 | 107 | 106 | 104 | 102 | 98 | 91 | 80 | 75 | 69 | 59 | 46 | 32 | 18 | 102~18 | |

| 6SS60/9 | 18.5 | 25 | 45 | 121 | 119 | 117 | 115 | 110 | 103 | 90 | 85 | 77 | 67 | 52 | 36 | 20 | 115~20 | |

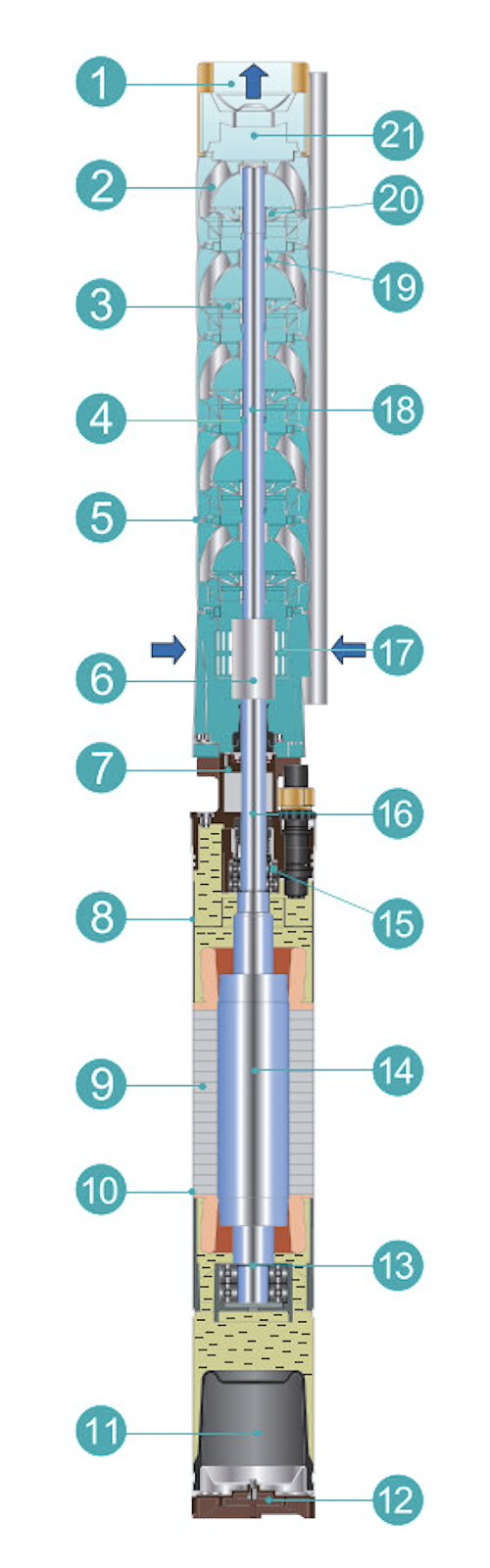

Components & Materials

|

|

No. | Component | Material |

| 1 | Discharge Chamber | Stainless Steel | |

| 2 | Guide Vanes | Stainless Steel | |

| 3 | Impeller | Stainless Steel | |

| 4 | Bearing Sleeve | Stainless Steel | |

| 5 | Cable Guard | Stainless Steel | |

| 6 | Shaft Coupling | Stainless Steel | |

| 7 | Oil Chamber | HT200 | |

| 8 | Waterproof Sleeve | PA66 | |

| 9 | Stator | —- | |

| 10 | Motor Housing | Stainless Steel | |

| 11 | Pressure Regulating Membrane | NBR | |

| 12 | Base | PA66 | |

| 13 | Bearing | 5.5~7.5Kw.7306B DT 9.2~15kW:7306BWG | |

| 14 | Rotor | AISI 304 + Steel 45# | |

| 15 | Bearing | 2×6205 | |

| 16 | Mechanical Seal | FP/25 A:S(PC) | |

| 17 | Inlet Part | Stainless Steel | |

| 18 | Pump Shaft | Stainless Steel | |

| 19 | Rubber Bearing | NBR | |

| 20 | L .ock Nut | Stainless Steel | |

| 21 | Valve Deck | Stainless Steel |

Application

- Domestic Water Supply: Suitable for household water needs, ensuring a steady and reliable source of water for daily activities.

- Irrigation and Small Water Works: Ideal for agricultural irrigation and managing small-scale water infrastructure, supporting crop growth and water distribution efficiently.

- Landscaping: Can be used to maintain and supply water for aesthetic and functional landscaping purposes, helping to nurture green spaces and gardens.

- Water Conservancy Systems: Plays a crucial role in water conservation efforts, aiding in the management and distribution of water resources to meet regional demands.

- Industrial Use: Meets the water requirements of various industrial processes in factories, providing essential support for manufacturing and production operations.

Application Limits

- Maximum Ambient Temperature: The pump is designed to operate effectively in environments with an ambient temperature of up to 40°C, ensuring reliable performance under typical outdoor temperatures.

- Sand Content Tolerance: Capable of handling water with a sand content of up to 0.01% by mass. This feature ensures durability and longevity in sandy or silty environments, preventing abrasion and clogging.

- Chemical Resistance:

- Hydrogen Sulfide: The pump can tolerate water containing up to 1.5 mg/L of hydrogen sulfide, which is beneficial for areas with minor contamination by this gas.

- Chloride Ions: It is also capable of managing chloride ion concentrations up to 400 mg/L, suitable for use in slightly saline water which is common in coastal areas or where groundwater has mild salinity.

- pH Range: The pump operates efficiently in water with a pH range from 6.5 to 8.5, accommodating slightly acidic to slightly alkaline water conditions, which covers most natural freshwater sources.

- Submersion Depth: Designed to be installed up to 70 meters below the static water level, making it highly effective for deep well applications, ensuring water extraction from significant depths.

FAQ

1.What is the maximum depth from which this pump can extract water?

The pump can operate effectively up to 70 meters below the static water table, making it suitable for deep wells.

2.Can this pump handle water with sand content?

Yes, it can handle water with a sand content of up to 0.01% in mass fraction. This capability helps prevent damage and wear from abrasive particles.

3.What are the limits for hydrogen sulfide and chloride ions in the water?

The pump tolerates up to 1.5 mg/L of hydrogen sulfide and up to 400 mg/L of chloride ions, accommodating environments with slight chemical contamination.

4.What is the operating pH range for this pump?

It operates efficiently in a pH range of 6.5 to 8.5, suitable for most natural water sources.

5.What temperature conditions is the pump designed for?

The pump is designed to function in ambient temperatures up to 40°C, ensuring reliability in warm climates.

6.Is this pump suitable for residential use?

Absolutely, it can be used for domestic water supply, ensuring adequate water delivery for household needs.

7.Can this pump be used for irrigation purposes?

Yes, it’s ideal for irrigation and small water works, providing sufficient flow and pressure to support agricultural activities.

8.What are some recommended maintenance tips for this pump?

Regular maintenance should include checking for sand and debris buildup, ensuring the motor is not overheating, and verifying the integrity of seals and bearings to ensure optimal performance and longevity.