BWI Series New Light Stainless Steel Horizontal Multistage Centrifugal Pump

Introducing the BWI series, a versatile and high-performance horizontal multistage centrifugal pump that delivers exceptional results across a wide range of applications. Crafted with precision and care, this non-self-priming pump boasts a sleek, lightweight stainless steel design that sets it apart from the competition.

What really makes the BWI series stand out is its impressive combination of high efficiency, low noise levels, and unparalleled stability during operation. The streamlined, compact construction not only saves space but also makes installation, use, and maintenance a breeze. With ease of use and durability at the forefront of its design, this pump is built to withstand the demands of even the most challenging environments.

At the heart of the BWI series is the overflow component, meticulously fabricated using top-grade 304 stainless steel that has been skillfully stamped and welded to ensure superior quality and longevity. This attention to detail and commitment to using only the finest materials sets the BWI series apart as a leader in its class.

Whether you’re in need of a reliable solution for industrial applications, water treatment, or any other demanding task, the BWI series new light stainless steel horizontal multistage centrifugal pump delivers the performance and dependability you can count on, time and time again.

Application Limits:

The BWI series light stainless steel horizontal multistage centrifugal pump is an ideal choice for handling thin, clean, non-combustible, and non-explosive liquids that are free of solid particles or fibers. This versatile pump is well-suited for delivering a variety of media, including tap water, alkaline mineral water, softened water, and mildly-corrosive substances.

When pumping media with higher density or viscosity than water, it is essential to consider using a motor with greater power to ensure optimal performance. The BWI series pump is designed to operate efficiently within a wide temperature range, with the normal temperature type handling media between 0°C and +68°C (32°F to +154°F) and the hot water type capable of handling temperatures from 68°C to +120°C (154°F to +248°F).

This pump is built to withstand ambient temperatures ranging from -15°C to +40°C (5°F to +104°F) and can operate at a maximum pressure of 1.0MPa (145 psi). With its durable construction and adaptability to various liquid types and operating conditions, the BWI series light stainless steel horizontal multistage centrifugal pump is a reliable choice for a wide range of applications.

Applications:

The BWI series light stainless steel horizontal multistage centrifugal pump is a versatile solution for a wide array of applications, including:

- HVAC and cooling systems: This pump is well-suited for use in air conditioning systems and chillers, ensuring efficient circulation and heat transfer.

- Water supply, treatment, and pressurization: Whether it’s for water supply, treatment, or pressurization systems, the BWI series pump delivers reliable performance and consistent results.

- Industrial applications: From filling machinery and environmental engineering to industrial cleaning and fertilization systems, this pump can handle a variety of industrial tasks with ease.

- Aquaculture and metering systems: The BWI series pump is an ideal choice for aquaculture and metering applications, providing accurate and dependable performance in these sensitive environments.

With its ability to adapt to diverse applications and its robust construction, the BWI series light stainless steel horizontal multistage centrifugal pump is a go-to choice for professionals seeking a high-quality, efficient, and long-lasting pumping solution.

Optional Available On Request:

- Protection class: IP55

- Insulation class: F

- Working method: S1

- Voltage level: 220V/50Hz,380V/50Hz

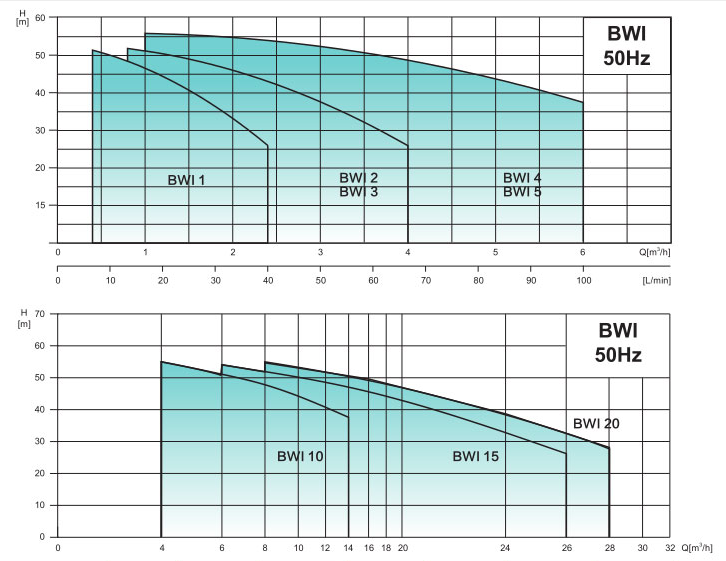

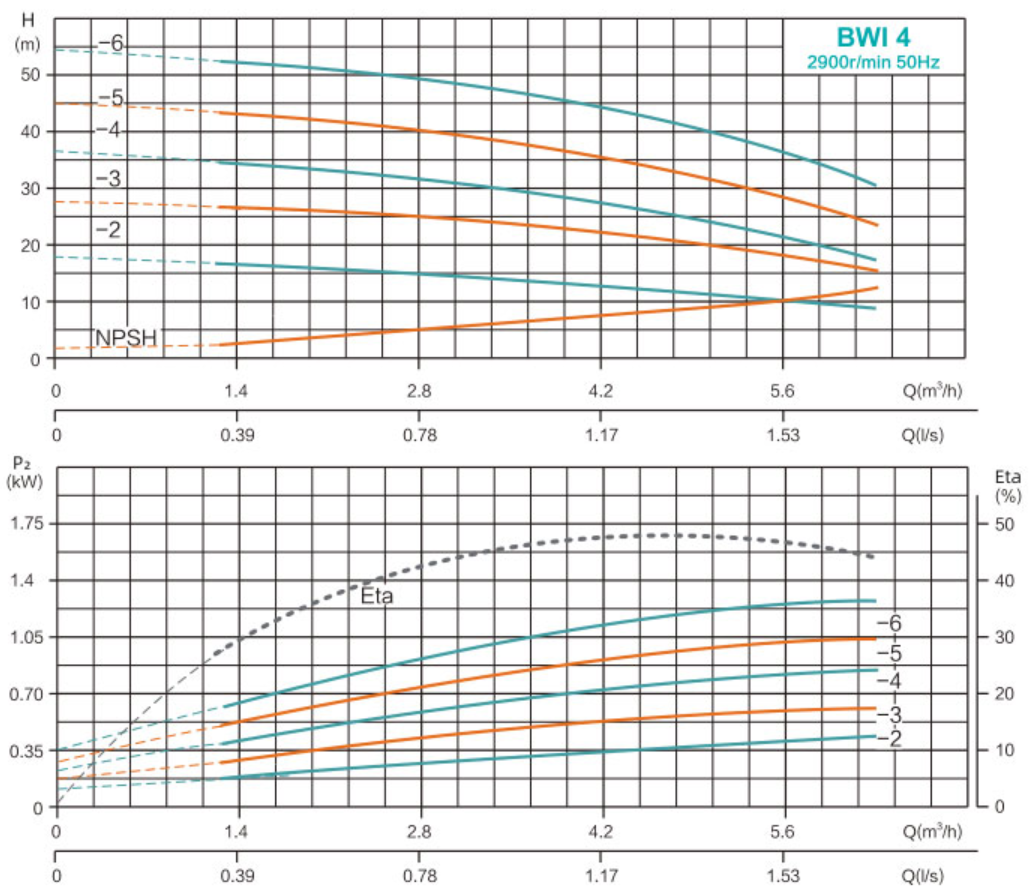

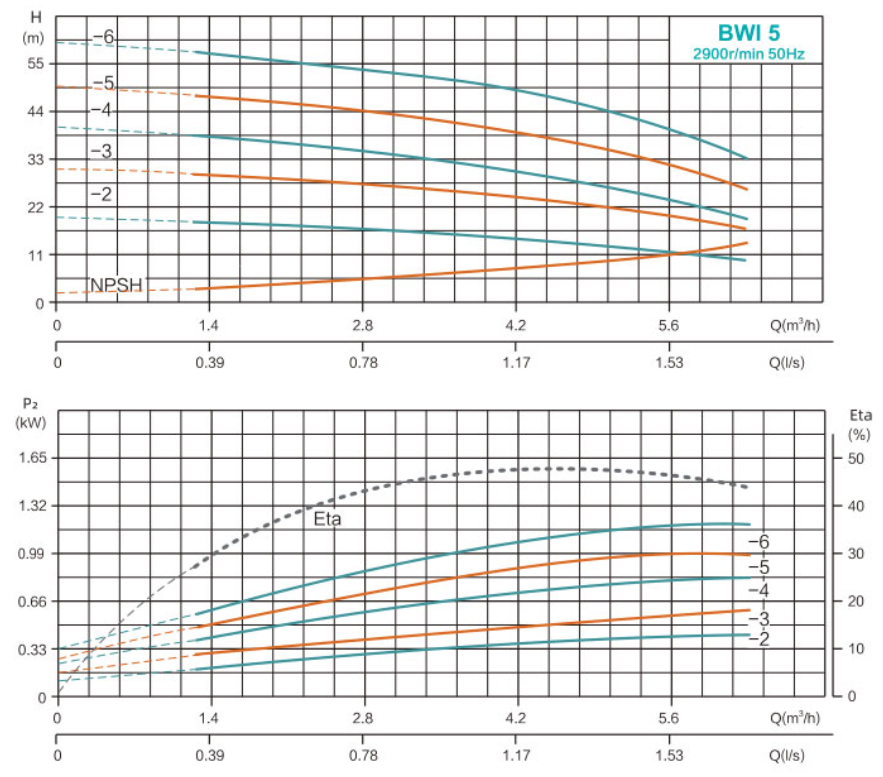

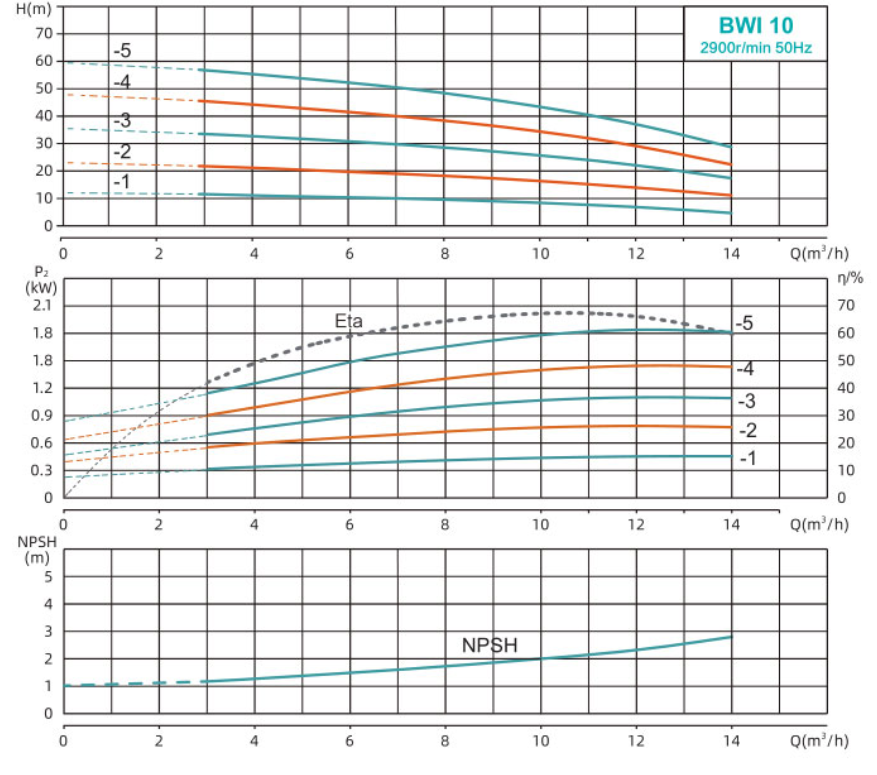

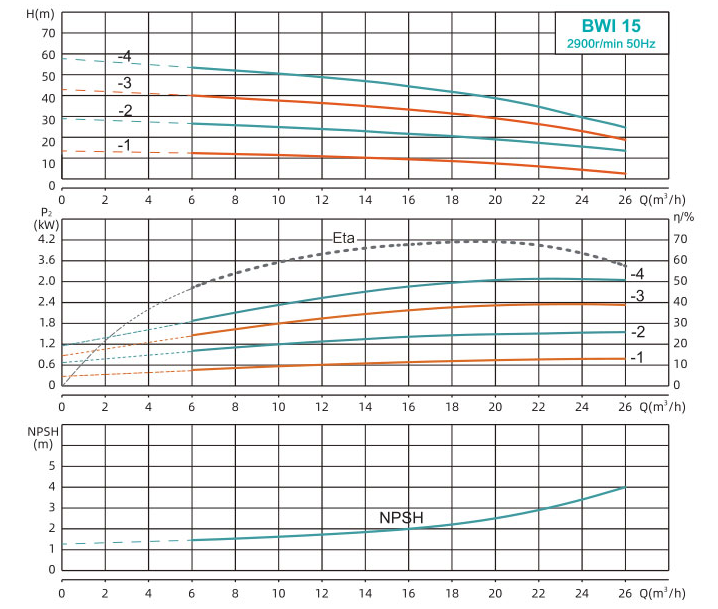

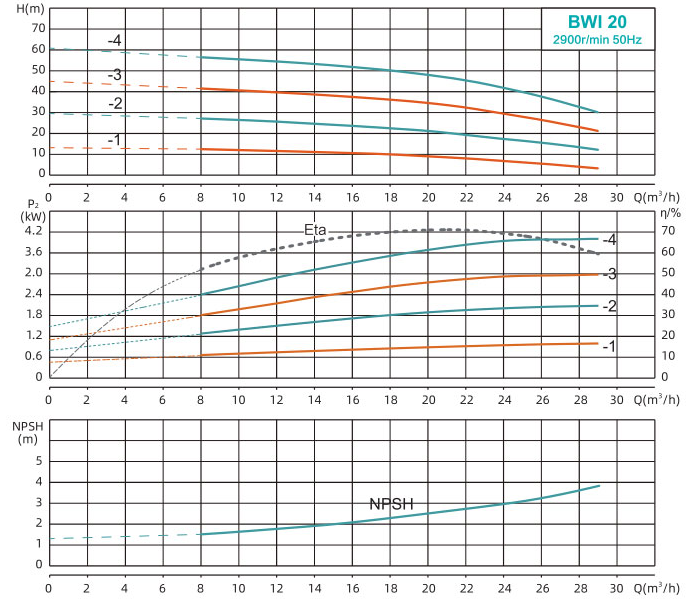

Performance Curve:

| Model | Rated flow (m³/h) | Flow range (m³/h) | Maximum pressure (bar) | Motor power (kW) | Maximum efficiency (%) | Temperature range (°C) | Inlet | Outlet |

| BWI 1 | 1 | 0.4-2.4 | 5.1 | 0.25 -0.37 | 28 | 0°C~ +68°C | G1 | G1 |

| BWI 2 | 2 | 0.8-4 | 5.6 | 0.25 -0.75 | 39 | G1 | G1 | |

| BWI 3 | 3 | 0.8-4 | 5.6 | 0.25 -0.75 | 49 | G1 | G1 | |

| BWI 4 | 4 | 1-6 | 5.6 | 0.37-1.3 | 52 | G1 1/4 | G1 | |

| BWI 5 | 5 | 1-6 | 5.6 | 0.37-1.3 | 56 | G1 1/4 | G1 | |

| BWI 10 | 10 | 5-14 | 10 | 0.55-1.8 | 68 | G1 1/2 | G1 1/2 | |

| BWl15 | 15 | 8-24 | 10 | 0.75-3 | 66 | G2 | G2 | |

| BWI 20 | 20 | 10-29 | 10 | 1.1-4 | 68 | G2 | G2 |

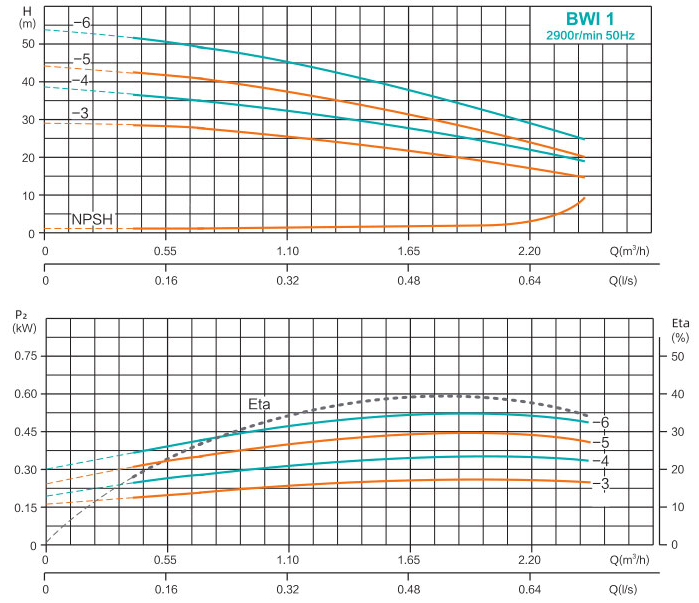

BWI 1 Performance Curve:

| Model | Power | Q(m³/h) | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | 2.2 | 2.4 |

| BWI 1-3 | 0.25 | H(m) | 29 | 28.5 | 26 | 25 | 24.5 | 23.5 | 22 | 21 | 19 | 17 | 16 |

| BWI 1-4 | 0.37 | 37 | 36 | 35 | 33 | 32 | 30 | 28 | 27 | 26 | 22 | 20 | |

| BWI 1-5 | 0.37 | 43 | 42 | 41 | 38 | 36 | 34 | 32 | 29 | 27 | 25 | 22 |

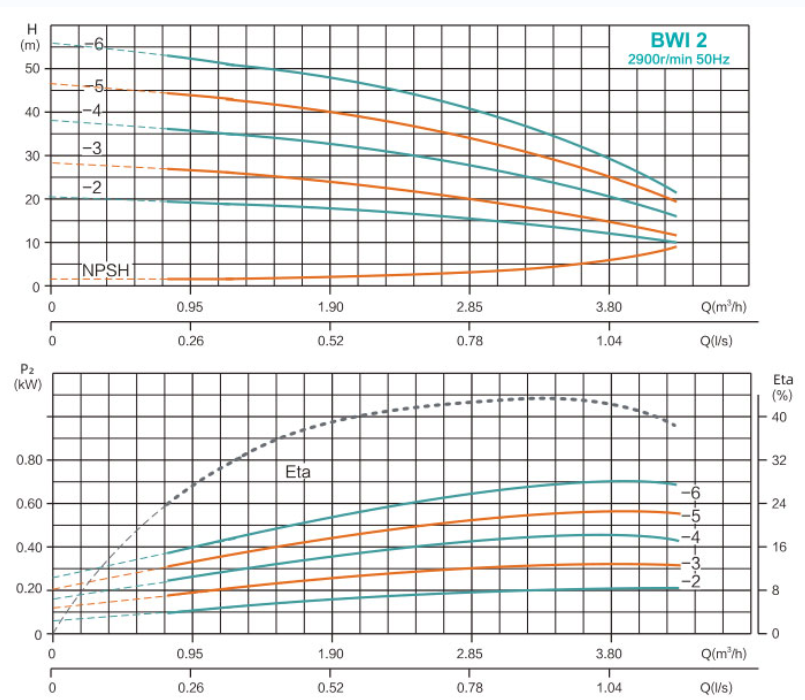

BWI 2 Performance Curve:

| Model | Power | Q (m³/h) | 0.8 | 1.2 | 1.6 | 2.0 | 2.4 | 2.8 | 3.2 | 3.6 | 4.0 |

| BWI 2-2 | 0.25 | H(m) | 18.5 | 17.5 | 17 | 16 | 15 | 14 | 12 | 11 | 9.5 |

| BWI 2-3 | 0.37 | 26 | 25 | 24 | 23 | 22 | 21 | 19 | 16 | 14 | |

| BWI 2-4 | 0.55 | 35 | 34 | 33 | 31 | 30 | 28 | 26 | 22 | 19 | |

| BWI 2-5 | 0.55 | 43 | 42 | 41 | 39 | 37 | 35 | 32 | 27.5 | 23 | |

| BWI 2-6 | 0.75 | 52 | 50.5 | 47 | 46 | 44 | 40 | 35 | 30.5 | 26 |

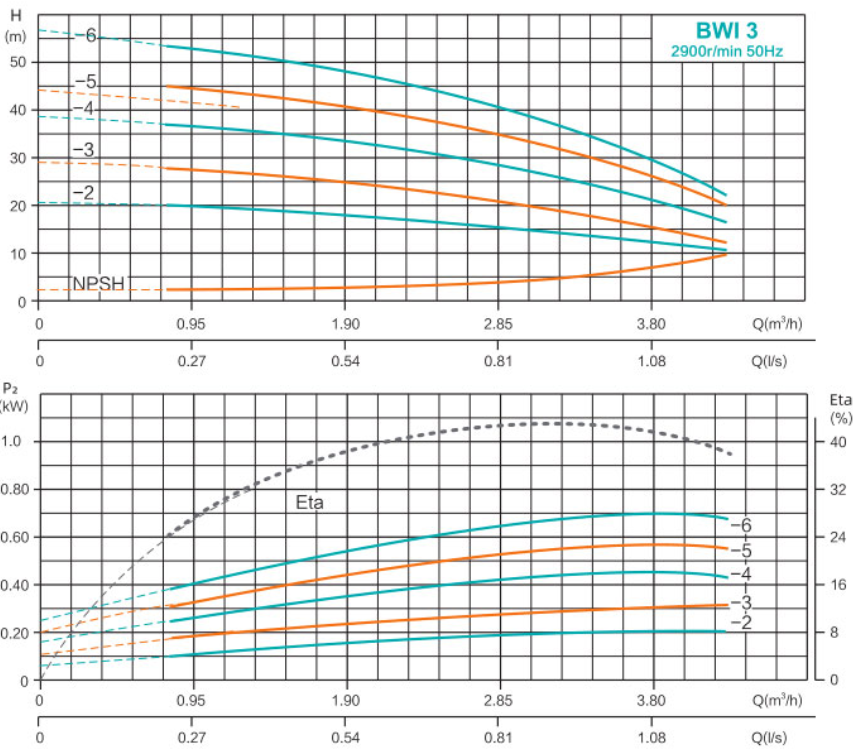

BWI 3 Performance Curve:

| Model | Power | Q (m³/h) | 0.8 | 1.2 | 1.6 | 2.0 | 2.4 | 2.8 | 3.0 | 3.2 | 3.6 | 4.0 |

| BWI 3-2 | 0.25 |

H(m) |

18.5 | 17.5 | 17 | 16 | 15 | 14 | 13 | 12 | 11 | 9.5 |

| BWI 3-3 | 0.37 | 26 | 25 | 24 | 23 | 22 | 21 | 20 | 19 | 16 | 14 | |

| BW1 3-4 | 0.55 | 35 | 34 | 33 | 31 | 30 | 28 | 27 | 26 | 22 | 19 | |

| BWI 3-5 | 0.55 | 43 | 42 | 41 | 39 | 37 | 35 | 33 | 32 | 27.5 | 23 | |

| BWI 3-6 | 0.75 | 52 | 50.5 | 47 | 46 | 44 | 40 | 37 | 35 | 30.5 | 26 |

BWI 4 Performance Curve:

| Model | Power | Q(m³/h) | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 |

| BWI 4-2 | 0.37 |

H(m) |

18.5 | 18 | 17.5 | 17 | 16 | 15.5 | 15 | 13.5 | 13 | 11 | 10 |

| BWI 4-3 | 0.55 | 29 | 28.5 | 28 | 27 | 26.5 | 25.5 | 25 | 23 | 22 | 20 | 18 | |

| BWI 4-4 | 0.75 | 38 | 37 | 36 | 34 | 33.5 | 32 | 30 | 28 | 27 | 24 | 20 | |

| BWI 4-5 | 1.0 | 47 | 46 | 45 | 44 | 42.5 | 41 | 40 | 36 | 35 | 32 | 27 | |

| BWI 4-6 | 1.3 | 56.5 | 55 | 54 | 53 | 52.5 | 51 | 49 | 45 | 44 | 42 | 36 |

BWI 5 Performance Curve:

| Model | Power | Q (m³/h) | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 |

| BWI 5-2 | 0.37 |

H(m) |

18.5 | 18 | 17.5 | 17 | 16 | 15.5 | 15 | 13.5 | 13 | 11 | 10 |

| BWI 5-3 | 0.55 | 29 | 28.5 | 28 | 27 | 26.5 | 25.5 | 25 | 23 | 22 | 20 | 18 | |

| BWI 5-4 | 0.75 | 38 | 37 | 36 | 34 | 33.5 | 32 | 30 | 28 | 27 | 24 | 20 | |

| BWI 5-5 | 1 | 47 | 46 | 45 | 44 | 42.5 | 41 | 40 | 36 | 35 | 32 | 27 | |

| BWI 5-6 | 1.2 | 56.5 | 55 | 54 | 53 | 52.5 | 51 | 49 | 45 | 44 | 42 | 36 |

BWI 10 Performance Curve:

| Model | Power | Q (m³/h) | 0 | 5 | 6 | 8 | 10 | 12 | 14 |

| BWI 10-1 | 0.55 |

H(m) |

12 | 11 | 10.5 | 9.5 | 8 | 7 | 4.5 |

| BWI 10-2 | 0.75 | 23 | 20.5 | 19,5 | 18 | 16.5 | 14 | 11 | |

| BWI 10-3 | 1.1 | 34.5 | 32 | 31 | 28.5 | 25.5 | 22 | 17.5 | |

| BWI 10-4 | 1.5 | 48 | 43 | 41.5 | 38 | 34 | 29 | 22.5 | |

| BWI 10-5 | 1,8 | 59.5 | 53.5 | 52 | 48.5 | 43 | 37.3 | 28.5 |

BWI 15 Performance Curve:

| Model | Power | Q (m³/h) | 0 | 6 | 8 | 10 | 12 | 15 | 18 | 20 | 22 | 24 | 26 |

| BWI 15-1 | 0.75 |

H(m) |

13.5 | 12.5 | 12 | 11.5 | 10.8 | 10 | 8.5 | 7.5 | 6 | 4,5 | 3 |

| BWI 15-2 | 1.8 | 29 | 26.5 | 25.8 | 24.8 | 24 | 22.5 | 20.5 | 18.7 | 16.8 | 15.4 | 14 | |

| BWI 15-3 | 2.2 | 43 | 40 | 38.5 | 37.5 | 36.5 | 34 | 31.4 | 29 | 26.4 | 23 | 19.5 | |

| BWI 15-4 | 3 | 57.5 | 53.3 | 51.5 | 50.5 | 48.5 | 46 | 42 | 38 | 34.5 | 29.3 | 24.5 |

BWI 20 Performance Curve:

| Model | Power | Q (m³/h) | 0 | 10 | 12 | : 14 | 16 | 18 | 20 | 22 | 24 | 26 | 29 |

| BWI 20-1 | 1.1 | 13.5 | 12 | 11.5 | 11.1 | 10.5 | 10 | 9.5 | 8 | 6.8 | 5.5 | 3.2 | |

| BWI 20-2 | 2.2 | 30 | 27 | 26 | 25 | 25.5 | 24 | 23 | 20.3 | 18.5 | 18 | 13 | |

| BWI 20-3 | 3 | H(m) | 45 | 40.5 | 39.5 | 38.5 | 37.5 | 36.2 | 35 | 32.4 | 29.3 | 26.3 | 21 |

| BWI 20-4 | 4 | 60.2 | 55.5 | 54.5 | 53.2 | 51.8 | 50 | 47 | 45.2 | 42 | 37.3 | 30 |

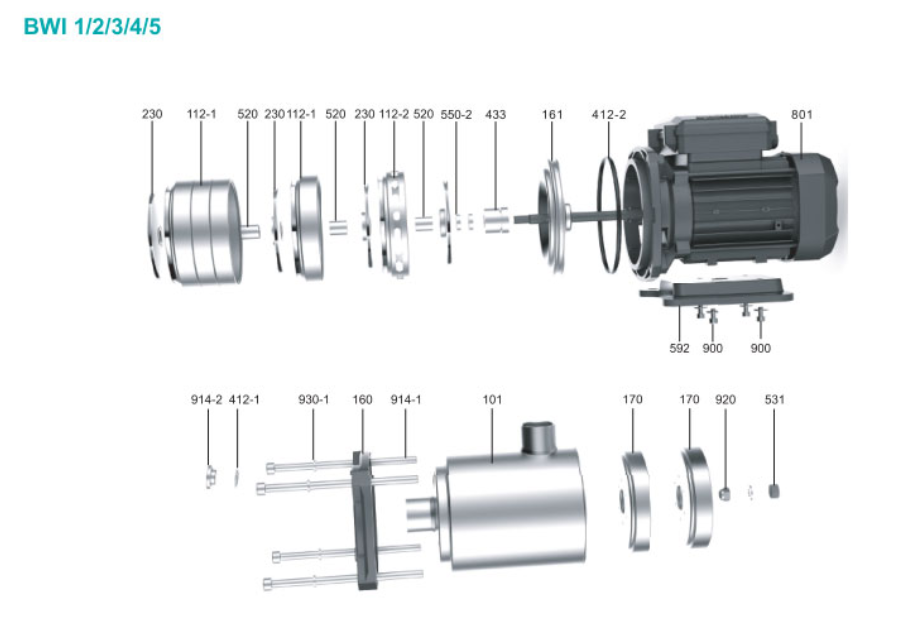

Components:

| No. | Component | No. | Component |

| 101 | Pressure cylinder | 520 | Oblong sleeve |

| 112-1 | Chamber | 531 | Bushing |

| 112-2 | Outlet chamber | 550-2 | Adjusting washer |

| 160 | Platen | 592 | Base plate |

| 161 | COVER AS-FRONT | 801 | Electric machinery |

| 170 | Inlet chamber | 900 | Hexagon flange bolt |

| 230 | Impeller | 914-1 | Hexagon socket head cap screw |

| 412-1 | 0-ring | 914-2 | Hexagon socket plug |

| 412-2 | 0-ring | 920 | Non-metallic insert hex lock nut |

| 433 | Shaft seal | 930-1 | Standard spring washer |

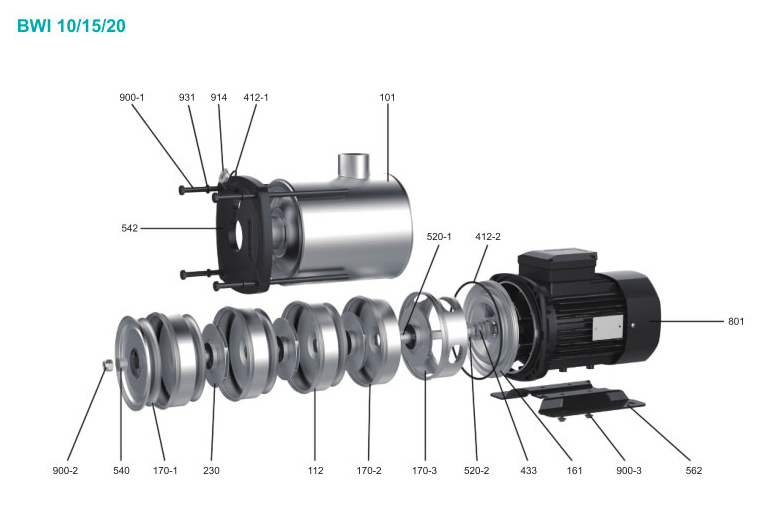

| No. | Component | No. | Component |

| 101 | Pressure Cylinder | 520-4 | Locking Shaft Sleeve |

| 112-2 | Guide Vane | 540 | Liner |

| 161-2 | Front Cover Assembly | 542 | Pressure Plate |

| 170 | Inlet Guide Vane | 562 | Base |

| 171 | Outlet Guide Vane | 801 | Motor |

| 170-3 | Outlet Guide Vane | 900 | Hexagonal Head Bolt |

| 230 | Impelle | 900-1 | 1 Type 1 Non-metallic Fitting Locking Nut |

| 412-2 | 0-ring Sealф160×3.55 | 900-3 | Hexagonal Flange Face Bolt M5x10 |

| 412-1 | O-ring Sealф12.5×2.65 | 914 | Hexagon Plug |

| 433 | Mechanical Seal | 931 | Double Spring Self-locking Washer |

| 520 | Long Oval Bushing |

FAQ:

Q: What makes the BWI series horizontal multistage centrifugal pump stand out from other pumps in its class?

A: The BWI series pump stands out due to its exceptional combination of high efficiency, low noise levels, and unparalleled stability during operation. Additionally, its sleek, compact design and use of top-grade 304 stainless steel set it apart from the competition.

Q: Is the BWI series pump easy to install, use, and maintain?

A: Yes, the streamlined and compact construction of the BWI series pump makes installation, use, and maintenance a breeze. This pump is designed with ease of use and durability in mind, ensuring a hassle-free experience for users.

Q: What types of liquids can the BWI series pump handle?

A: The BWI series pump is designed to handle thin, clean, non-combustible, and non-explosive liquids that are free of solid particles or fibers. This includes tap water, alkaline mineral water, softened water, and mildly-corrosive media.

Q: Can the BWI series pump be used for high-temperature applications?

A: Yes, the BWI series pump is available in two temperature ranges. The normal temperature type can handle media between 0°C and +68°C (32°F to +154°F), while the hot water type is capable of handling temperatures from 68°C to +120°C (154°F to +248°F).

Q: What is the maximum operating pressure of the BWI series pump?

A: The BWI series pump can operate at a maximum pressure of 1.0MPa (145 psi), making it suitable for a wide range of demanding applications.

Q: Is the BWI series pump suitable for industrial applications?

A: Yes, the BWI series pump is an excellent choice for various industrial applications, including filling machinery, environmental engineering, industrial cleaning, and more. Its durability and performance make it a reliable solution for demanding industrial tasks.