6 Inch Deep Well Pumps 6SS(K2) 344 GPM

The 6SS(K2) series, a standout in the 6-inch deep well pump category, delivers a remarkable flow rate of up to 344 gallons per minute (GPM), setting a new benchmark for efficiency and reliability. Engineered for optimal performance in extensive agricultural, industrial, and municipal applications, this pump is renowned for its durability and ability to handle high-volume water extraction with ease. Its robust design ensures consistent operation even in the most demanding environments, making it a top choice for those seeking a high-capacity solution. Ideal for deep wells, the 6SS(K2) offers a perfect blend of power and precision, embodying the pinnacle of pumping technology.

Features:

- Stainless Steel Pump Head: The pump head is crafted from premium stainless steel, providing exceptional resistance to corrosion and abrasive wear. This ensures longevity and consistent performance, even in harsh environments.

- Edible Oil Filled Motor: This unique feature ensures stable and reliable operation. The edible oil filling not only lubricates but also aids in cooling the motor, accompanied by a pressure-regulating membrane that maintains optimal performance under varying pressures.

- Controller Box for Enhanced Protection: The inclusion of a controller box provides comprehensive protection against potential electrical and mechanical failures. This feature safeguards the pump, ensuring uninterrupted operation and reducing maintenance needs.

- Versatile Installation Options: Designed for 6-inch or larger boreholes, this pump offers flexibility in installation, making it suitable for a wide range of applications, from residential to industrial settings.

- High-Flow Capability: The pump’s impressive 344 GPM flow rate is ideal for high-demand scenarios, ensuring ample water supply whether for irrigation, industrial processes, or municipal water supply.

- Energy-Efficient Operation: Despite its high power, the 6SS(K2) operates efficiently, reducing energy consumption and lowering operating costs over time, which is essential for long-term, large-scale applications.

- Low Maintenance Requirements: Thanks to its robust construction and quality materials, the pump requires minimal maintenance. This reliability translates to fewer downtimes and cost savings on repairs and servicing.

- Quiet Performance: Engineered to operate quietly, this pump minimizes noise pollution, making it an excellent choice for areas where noise is a concern, such as residential zones or tranquil rural settings.

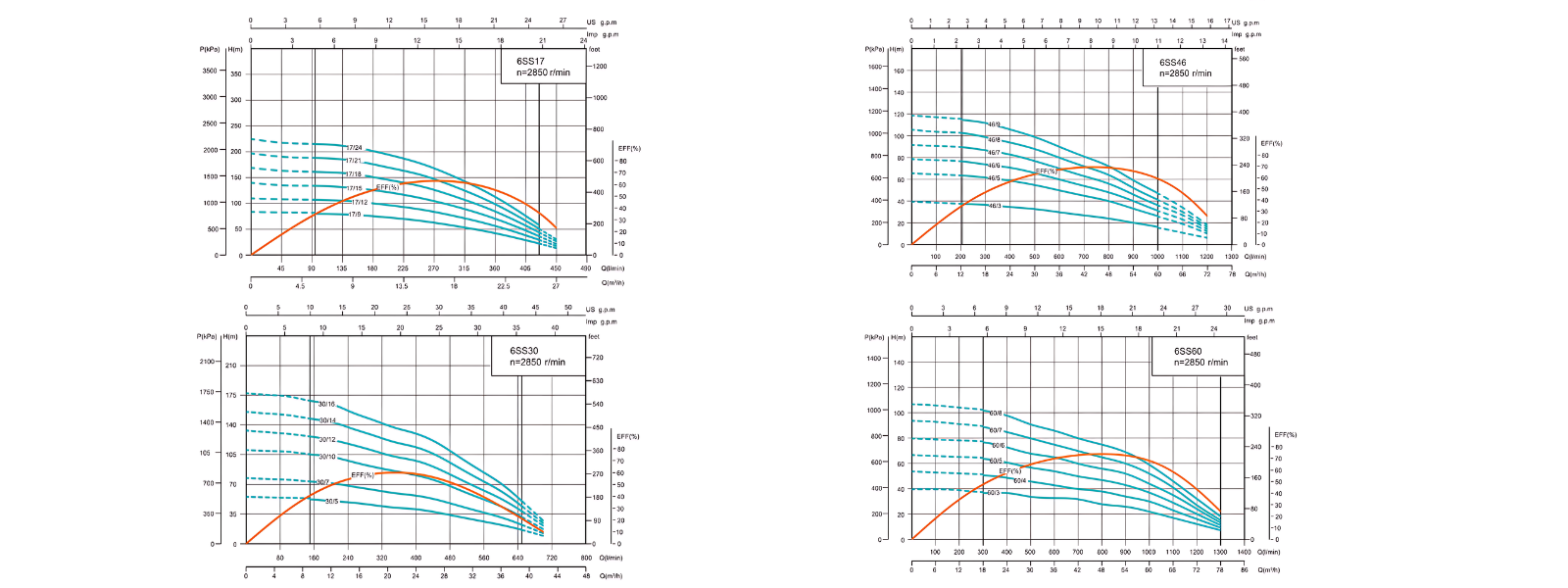

Performance Curve:

| Model | Power | Rate Current (A) | Flow | Head Range (m) | |||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | |

| 380V | 380V | l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | |||

| 6SS17/9 | 5.5 | 7.5 | 13 | H(m) | 85 | 82 | 81 | 79 | 74 | 67 | 57 | 45 | 30 | 13 | 81~38 |

| 65517/12 | 7.5 | 10 | 18 | 111 | 109 | 108 | 105 | 98 | 89 | 76 | 60 | 40 | 17 | 108~50 | |

| 6SS17/15 | 9.2 | 12.5 | 23 | 141 | 136 | 135 | 131 | 123 | 111 | 95 | 75 | 50 | 21 | 135~63 | |

| 65517/18 | 11 | 15 | 26 | 170 | 164 | 162 | 158 | 147 | 134 | 114 | 90 | 60 | 26 | 162~76 | |

| 65517/21 | 1; 3 | 17.5 | 33 | 198 | 191 | 189 | 184 | 171 | 156 | 133 | 105 | 70 | 30 | 189~88 | |

| 65517/24 | 15 | 20 | 35 | 226 | 218 | 216 | 210 | 196 | 178 | 152 | 120 | 80 | 34 | 216~101 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| 380V | 380V | l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | |||

| 65530/5 | 5.5 | 7.5 | 13 | H(m) | 56 | 55 | 54 | 53 | 51 | 49 | 46 | 43 | 41 | 37 | 32 | 27 | 272 | 16 | 9 | 53~16 |

| 6SS30/7 | 7.5 | 10 | 18 | 78 | 77 | 76 | 74 | 72 | 68 | 64 | 60 | 57 | 45 | 38 | 38 | 31 | 22 | 12 | 74~22 | |

| 65530/10 | 9.2 | 12.5 | 23 | 111 | 110 | 109 | 106 | 103 | 97 | 91 | 86 | 81 | 64 | 54 | 54 | 44 | 31 | 17 | 106~31 | |

| 65530/12 | 11 | 15 | 26 | 134 | 132 | 130 | 127 | 123 | 117 | 110 | 103 | 98 | 77 | 65 | 65 | 53 | 38 | 21 | 127~38 | |

| 6SS30/14 | 13 | 17.5 | 33 | 156 | 154 | 152 | 148 | 1 44 | 136 | 1, 28 | 120 | 114 | 90 | 76 | 76 | 62 | 44 | 24 | 148-44 | |

| 65530/16 | 15 | 20 | 35 | 178 | 176 | 174 | 169 | 165 | 155 | 146 | 137 | 130 | 103 | 87 | 87 | 71 | 50 | 27 | 169~50 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 6 | 9 | 12 | 15 | 18 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| 380V | 380V | l/min | 0 | 100 | 150 | 200 | 250 | 300 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | |||

| 65546/3 | 5.5 | 7.5 | 13 | H(m) | 40 | 39 | 38 | 37 | 35 | 33 | 30 | 27 | 24 | 20 | 16 | 1 1 | 6 | 38~16 |

| 6SS46/5 | 7.5 | 10 | 18 | 66 | 65 | 64 | 62 | 59 | 55 | 50 | 45 | 40 | 33 | 26 | 19 | 10 | 63-26 | |

| 65546/6 | 9.2 | 12.5 | 2; 3 | 79 | 78 | 77 | 74 | 71 | 66 | 60 | 54 | 48 | 40 | 31 | 23 | 12 | 76~31 | |

| 65S46/7 | 11 | 15 | 26 | 92 | 91 | 90 | 87 | 83 | 77 | 70 | 63 | 56 | 46 | 36 | 27 | 14 | 89-36 | |

| 65546/8 | 13 | 17.5 | 33 | 106 | 104 | 103 | 99 | 94 | 88 | 80 | 72 | 64 | 52 | 41 | 30 | 16 | 101~41 | |

| 6SS46/9 | 15 | 20 | 35 | 119 | 117 | 115 | 112 | 106 | 99 | 90 | 81 | 72 | 59 | 47 | 34 | 18 | 114-47 | |

| Model | Power | Rate Current (A) | Flow | Head Range (m) | ||||||||||||||

| Three-Phase | kW | HP | Three-Phase | m³/h | 0 | 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 | 72 | |

| 380V | 380V | l/min | 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |||

| 65546/3 | 5.5 | 7.5 | 13 | H(m) | 40 | 39 | 38 | 37 | 35 | 33 | 30 | 27 | 24 | 20 | 16 | 1 1 | 6 | 38~16 |

| 6SS46/5 | 7.5 | 10 | 18 | 66 | 65 | 64 | 62 | 59 | 55 | 50 | 45 | 40 | 33 | 26 | 19 | 10 | 63~26 | |

| 65S46/6 | 9.2 | 12.5 | 23 | 79 | 78 | 77 | 74 | 71 | 66 | 60 | 54 | 48 | 40 | 31 | 23 | 12 | 76~31 | |

| 6SS46/7 | 11 | 15 | 26 | 92 | 91 | 90 | 87 | 83 | 77 | 70 | 63 | 56 | 46 | 36 | 27 | 14 | 89-36 | |

| 65S46/8 | 13 | 17.5 | 33 | 106 | 104 | 103 | 99 | 94 | 88 | 80 | 72 | 64 | 52 | 41 | 30 | 16 | 101~41 | |

| 6SS46/9 | 15 | 20 | 35 | 119 | 117 | 115 | 112 | 106 | 99 | 90 | 81 | 72 | 59 | 47 | 34 | 18 | 114-47 | |

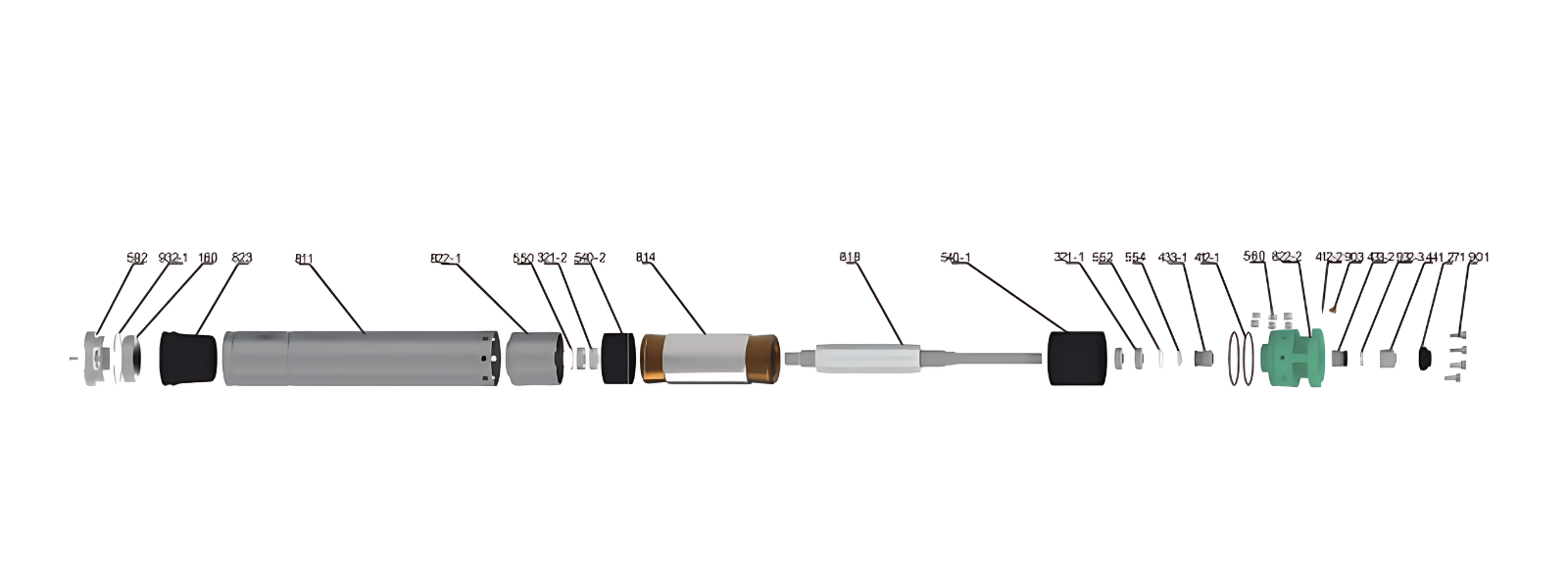

Components & Material:

| No. | Part name | No. | Part name |

|---|---|---|---|

| 160 | Inlet joint | 560 | Locating sleeve |

| 271 | Sand shaking sleeve | 592 | Base |

| 321-1 | Deep groove ball bearing | 811 | Casing |

| 321-2 | Angular contact ball bearing | 814 | Stator core with winding |

| 412-1 | O-ring | 818 | Rotor |

| 412-2 | O-ring | 822-1 | Lower bearing block |

| 433-1 | Mechanical seal | 822-2 | Oil chamber |

| 433-2 | Mechanical seal | 823 | Pressure regulating film |

| 441 | Stainless steel sleeve | 901 | Outer hexagon flat screw |

| 540-1 | Upper spacer sleeve | 903 | Vent cock |

| 540-2 | Lower spacer sleeve | 932-1 | Retaining ring |

| 550 | Pump shaft gasket | 932-2 | Circlip for shaft |

| 552 | Wave spring | ||

| 554 | Flat washer |

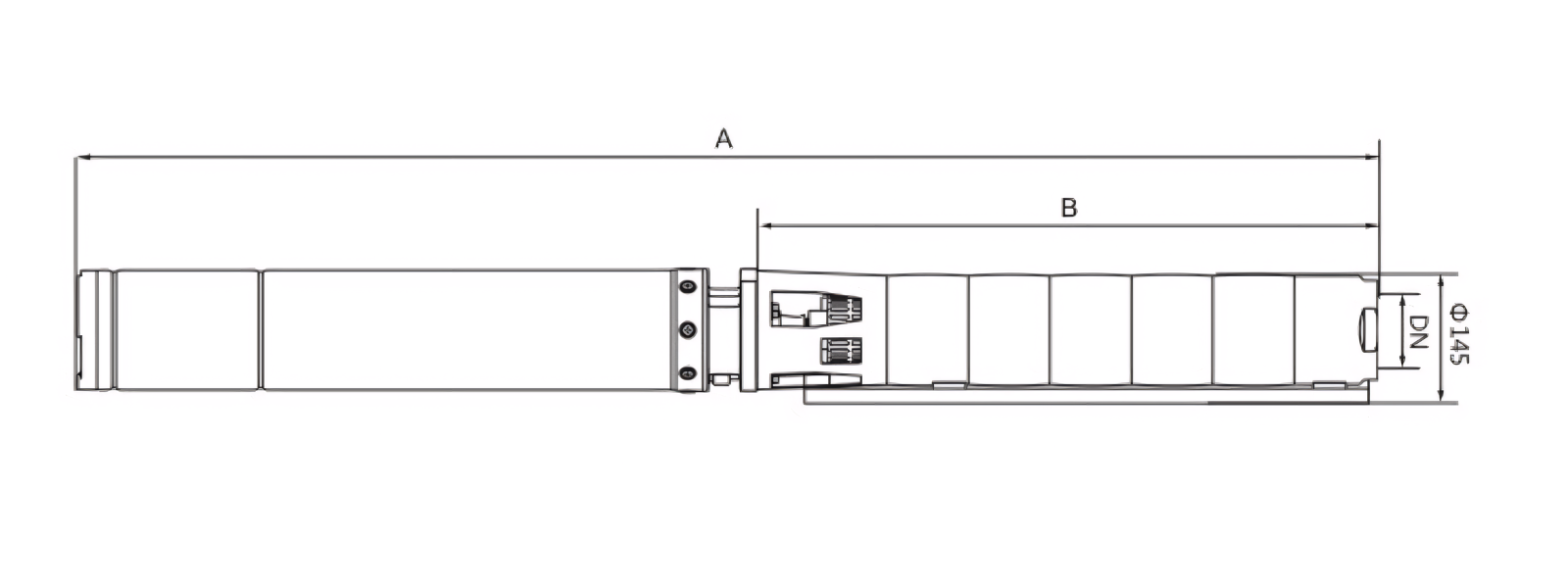

Dimensions & Weight:

| Model | Pipe Connection (DN) | Dim. (mm) | N.W.(kg) | ||

| Three-phase | B | A Three-phase | Body(kg) | Motor(kg) | |

| 65S17/9 | G3 | 817 | 1618 | 15.2 | 40 |

| 65S17/12 | 998 | 1864 | 19.1 | 45 | |

| 65S17/15 | 1180 | 2106 | 23 | 50 | |

| 65S17/18 | 1361 | 2357 | 26.9 | 58 | |

| 65S17/21 | 1543 | 2597 | 30.8 | 64 | |

| 65S17/24 | 1724 | 2817 | 34.7 | 67 | |

| 65S30/5 | 752 | 1553 | 12.5 | 40 | |

| 65S30/7 | 944 | 1810 | 16.1 | 45 | |

| 65S30/10 | 1232 | 2159 | 21.5 | 50 | |

| 65S30/12 | 1424 | 2420 | 25.1 | 58 | |

| 65S30/14 | 1616 | 2670 | 28.7 | 64 | |

| 65S30/16 | 1808 | 2901 | 32.3 | 67 | |

| 65S46/3 | 611 | 1412 | 11 | 40 | |

| 65S46/5 | 837 | 1703 | 16 | 45 | |

| 65S46/6 | 950 | 1876 | 18.5 | 50 | |

| 65S46/7 | 1063 | 2059 | 21 | 58 | |

| 65S46/8 | 1176 | 2230 | 23.5 | 64 | |

| 65S46/9 | 1289 | 2382 | 26 | 67 | |

| 65S60/3 | 611 | 1412 | 14 | 40 | |

| 65S60/4 | 724 | 1590 | 17.5 | 45 | |

| 65S60/5 | 837 | 1763 | 21 | 50 | |

| 65S60/6 | 950 | 1946 | 24.5 | 58 | |

| 65S60/7 | 1063 | 2117 | 28 | 64 | |

| 65S60/8 | 1176 | 2269 | 31.5 | 67 | |

| Model | Pipe Connection (DN) | Dim. (mm) | N.W.(kg) | ||

| Three-phase | B | A Three-phase | Body(kg) | Motor(kg) | |

| 65517/9-5.5K2 | G3 | 676 | 1197 | 12.5 | 31.3 |

| 65517/12-7.5K2 | 814 | 1395 | 15.5 | 36.8 | |

| 65517/15-9.2K2 | 952 | 1593 | 18.5 | 42 | |

| 65517/18-11K2 | 1090 | 1801 | 21 | 50 | |

| 65517/21-13K2 | 1228 | 1999 | 30.8 | 56 | |

| 65517/24-15K2 | 1366 | 2177 | 27 | 60 | |

| 65530/5-5.5K2 | 712 | 1233 | 12 | 31.3 | |

| 65530/7-7.5K2 | 892 | 1473 | 15.5 | 36.8 | |

| 65530/10-9.2K2 | 1162 | 1803 | 20 | 42 | |

| 65530/12-11K2 | 1342 | 2053 | 24 | 50 | |

| 65530/14-13K2 | 1522 | 2401 | 27 | 56 | |

| 65530/16-15K2 | 1702 | 2513 | 30 | 60 | |

| 65546/3-5.5K2 | 598 | 1119 | 9.5 | 31.3 | |

| 65546/5-7.5K2 | 822 | 1403 | 14 | 36.8 | |

| 65546/6-9.2K2 | 934 | 1575 | 16 | 42 | |

| 65546/7-11K2 | 1046 | 1757 | 18.5 | 50 | |

| 65546/8-13K2 | 1158 | 1929 | 20 | 56 | |

| 65546/9-15K2 | 1270 | 2081 | 22 | 60 | |

| 65560/3-5.5K2 | 598 | 1119 | 10 | 31.3 | |

| 65560/4-7.5K2 | 710 | 1291 | 12 | 36.8 | |

| 65560/5-9.2K2 | 822 | 1571 | 14 | 42 | |

| 65560/6-11K2 | 934 | 1645 | 16.5 | 50 | |

| 65560/7-13K2 | 1046 | 1817 | 18.5 | 56 | |

| 65560/8-15K2 | 1158 | 1969 | 21 | 60 | |

Application:

- Building Construction Work: In the realm of construction, the 6SS(K2) plays a pivotal role in providing water for various construction activities. It ensures a steady and reliable water supply for concrete mixing, site preparation, dust control, and other construction-related tasks. Its robust design can withstand the rigors of a construction site, providing consistent performance under challenging conditions.

- Domestic Water Supply: This pump is ideal for residential complexes, especially those with deep wells. It ensures a consistent and ample supply of water for daily household needs, including drinking, cooking, bathing, and cleaning. The pump’s efficiency and reliability make it a preferred choice for home water supply systems.

- Irrigation and Small Water Works: For agricultural settings and small-scale water projects, the 6SS(K2) is a boon. Its high flow rate efficiently meets the demands of irrigation, facilitating water distribution to fields and crops. This is vital for agricultural productivity and sustainability in rural and farming communities.

- Landscaping: In landscaping, water is a critical element for maintaining gardens, parks, and green spaces. The 6SS(K2) ensures an adequate and controlled water supply for watering plants, maintaining ponds and fountains, and other landscaping needs, helping to create and sustain lush, vibrant environments.

- Water Conservancy Systems: The pump is instrumental in water conservation efforts, particularly in managing and distributing water in reservoirs, dams, and canals. Its robustness and efficiency support the effective management of water resources, which is crucial for ecological balance and sustainability.

- Factory Use: For industrial settings, the 6SS(K2) provides a reliable water supply for various processes, including cooling, processing, cleaning, and other industrial needs. Its capacity to handle high volumes makes it suitable for factories and manufacturing plants, where a consistent water flow is essential for uninterrupted production.

Application Limits

- Maximum Ambient Temperature: The pump is designed to operate effectively in environments with ambient temperatures up to 40℃ (104°F). This makes it suitable for most climates, but care should be taken in extremely hot conditions to prevent overheating and ensure the motor’s longevity.

- Sand Tolerance: The pump can handle up to 100 grams of sand per cubic meter of water. This level of tolerance is suitable for most well waters but highlights the need for a pre-filtering system in sandy environments to prevent abrasion and wear of the internal components.

- Chemical Resistance: It can handle hydrogen sulfide up to 1.5mg/L and chloride ions up to 400mg/L. These specifications are important in areas where water might have a higher mineral content or slight contamination. The materials used in the pump are chosen to resist these chemical levels, ensuring durability.

- pH Range: The optimal pH range for the water being pumped is between 6.5 to 8.5. This range covers most natural water sources. However, water outside this pH range might require treatment to prevent corrosion or scaling in the pump.

- Operating Depth: The pump is designed to operate at a maximum of 70 meters below the static water table. This depth range allows for effective water extraction from deep wells, ensuring a reliable water supply for various applications.

FAQ:

Q: What is the maximum flow rate of the 6SS(K2) series pump?

A: The 6SS(K2) series pump can achieve a maximum flow rate of up to 344 gallons per minute (GPM).

Q: Can the 6SS(K2) pump be used in environments with high ambient temperatures?

A: Yes, it can operate effectively in environments with ambient temperatures up to 40°C (104°F). However, it’s important to ensure adequate cooling and ventilation to prevent overheating.

Q: What is the maximum permissible quantity of sand in the water for the 6SS(K2) pump?

A: The pump can handle up to 100 grams of sand per cubic meter of water. Using a pre-filter is advised in sandy conditions to extend the pump’s lifespan.

Q: Is the 6SS(K2) suitable for water with high mineral content?

A: Yes, it can handle water with hydrogen sulfide up to 1.5mg/L and chloride ions up to 400mg/L. However, water treatment may be necessary if these levels are exceeded to prevent damage.

Q: What pH range of water is suitable for the 6SS(K2) pump?

A: The optimal pH range for this pump is between 6.5 to 8.5, covering most natural water sources.

Q: How deep can the 6SS(K2) pump be installed?

A: The pump is designed for operation at a maximum depth of 70 meters below the static water table.

Q: Can the 6SS(K2) be used for both residential and industrial applications?

A: Absolutely, the 6SS(K2) is versatile and robust, making it suitable for a wide range of applications including residential, agricultural, industrial, and municipal use.

Q: What kind of maintenance does the 6SS(K2) pump require?

A: Regular maintenance includes checking the motor condition, ensuring the filter is clean, and monitoring the pump’s performance. The pump’s durable design minimizes the need for frequent maintenance.